Compounding Aseptic Isolators

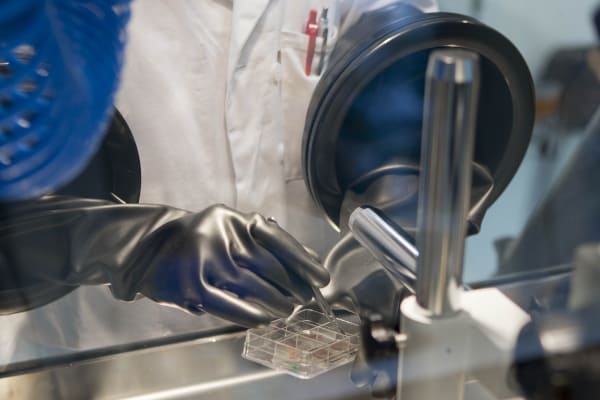

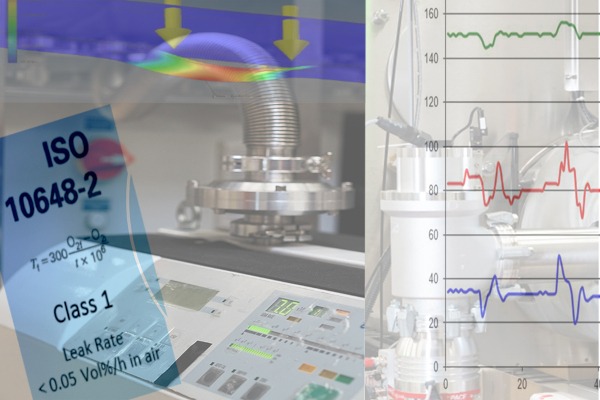

Aseptic drug preparation isolators are made up of walls. The integrity of these walls must be checked regularly to ensure that there are no leaks and that the main chamber is completely sealed. Isolators are also equipped with HEPA filters upstream and downstream and a ventilation system. This can be integrated into a vacuum or overpressure isolator.

For aseptic applications, such as drug preparation, the use of an isolator is the best solution due to its performance. The equipment enables the preparation of medicines in aseptic air and in a controlled and purified atmosphere. Depending on how it is used, the isolator offers a controlled atmosphere zone with laminar air flow or operates in overpressure or underpressure. In all cases, the purpose of using an isolator is to protect drug preparations from contaminants.

The isolator incorporates transfer systems for the introduction and removal of prepared drugs and for the disposal of waste materials under aseptic conditions. The isolator and all accompanying equipment must be sterilized. The isolator must ensure compliance with all the requirements dictated by each preparation of advanced therapy medicinal products, each dosing and weighing operation, etc.

Characteristics of Jacomex Aseptic Isolators

Jacomex designs and manufactures containment equipment for various sectors, including the pharmaceutical sector. Isolators for the preparation of medicines that the company can provide have the following general characteristics:

- Positive or negative pressure;

- Laminar, unidirectional or turbulent flow ventilation;

- Tight flow with or without internal storage;

- HEPA or ULPA filtration;

- Safe transfer systems;

- Side-by-side or face-to-face workstations, as required.

For drug preparations, Jacomex ensures that the isolator is designed in full compliance with GAPMP5, ISO and PIC/S, 21 CFR PART 11, GMP and FDA standards.

Isolators are a modern piece of technology from which the pharmaceutical industry can benefit. Compared to sterile cleanrooms, isolators offer a far superior sterile environment, with particularly effective aseptic processes, procedure validation and sterility testing.

The integration of software and options makes it easy to control and monitor drug preparations. It is also easy to record and adjust humidity levels, temperatures and pressures. During inspections by the authorities, the data collected is of great use. The traceability of the products in each stage of preparation is also proven with the help of the documents provided by the company.

Taking up less space, the isolators reduce your renovation costs for a low investment. Your operational costs will also be reduced, as their maintenance and upkeep is also reduced.

Jacomex can also supply customised aseptic drug preparation isolators with accessories and options to meet the strict requirements of your preparations.