Glove boxes for Additive Manufacturing Applications

Additive manufacturing (FA) or 3D printing is a technique widely used today in the industry for applications in aeronautics, medical or any other field requiring the implementation of metal powders (titanium, aluminum, alloys, stainless steel, superalloys …).

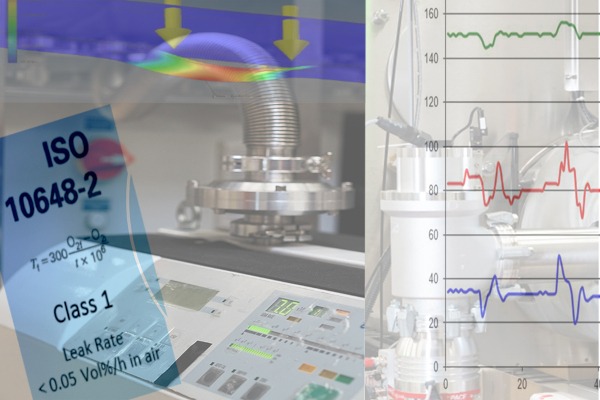

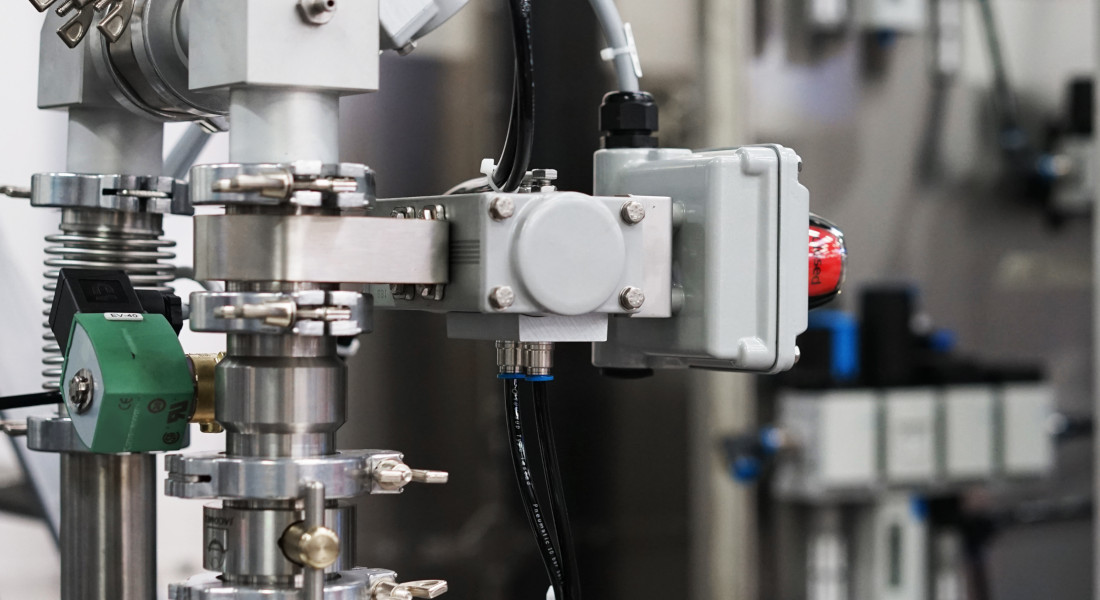

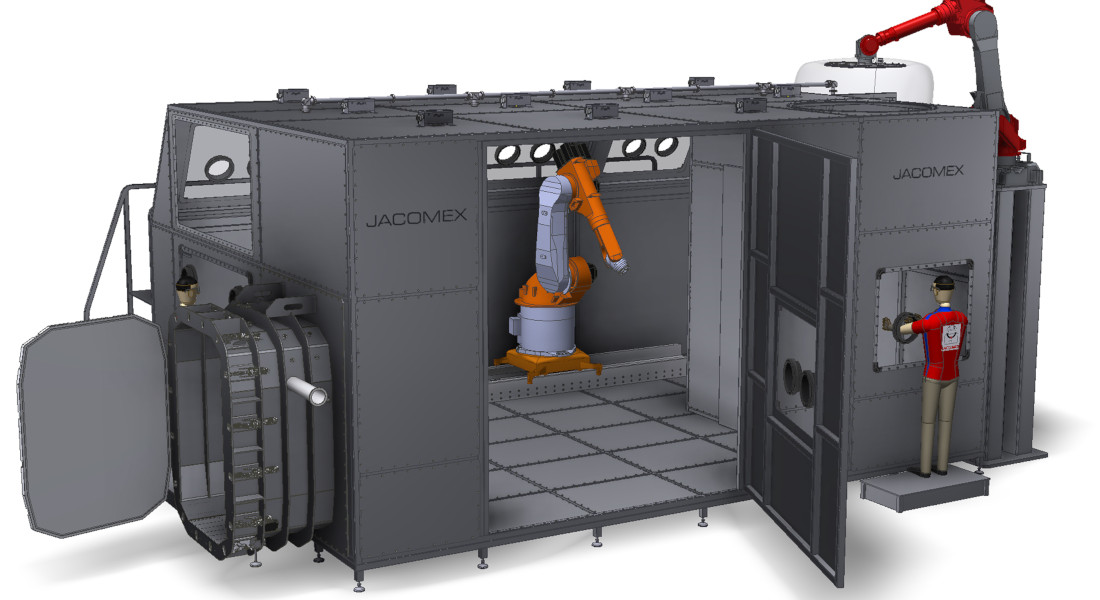

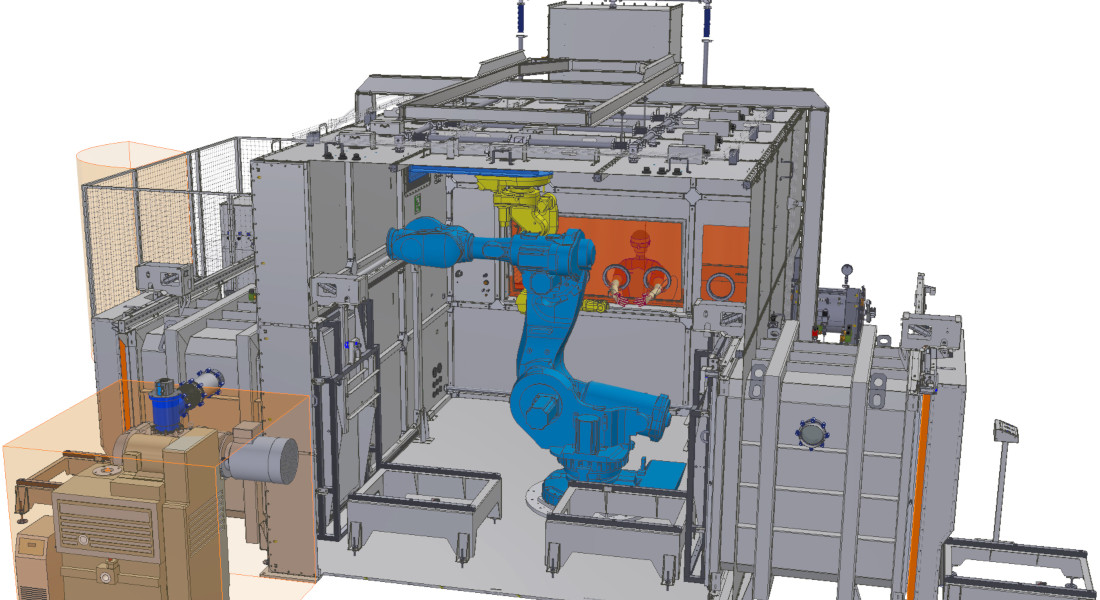

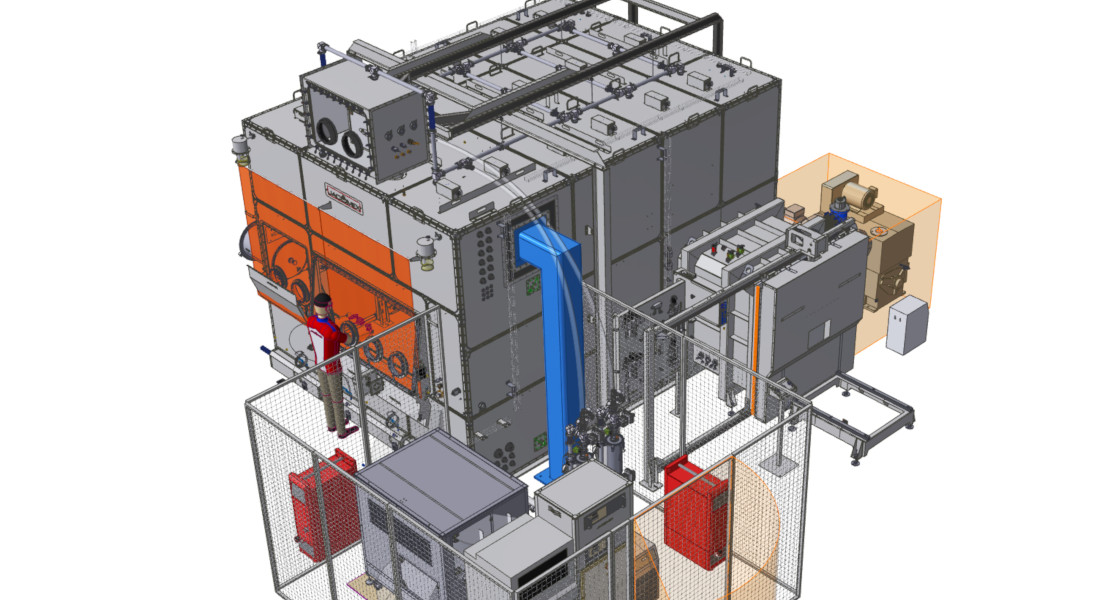

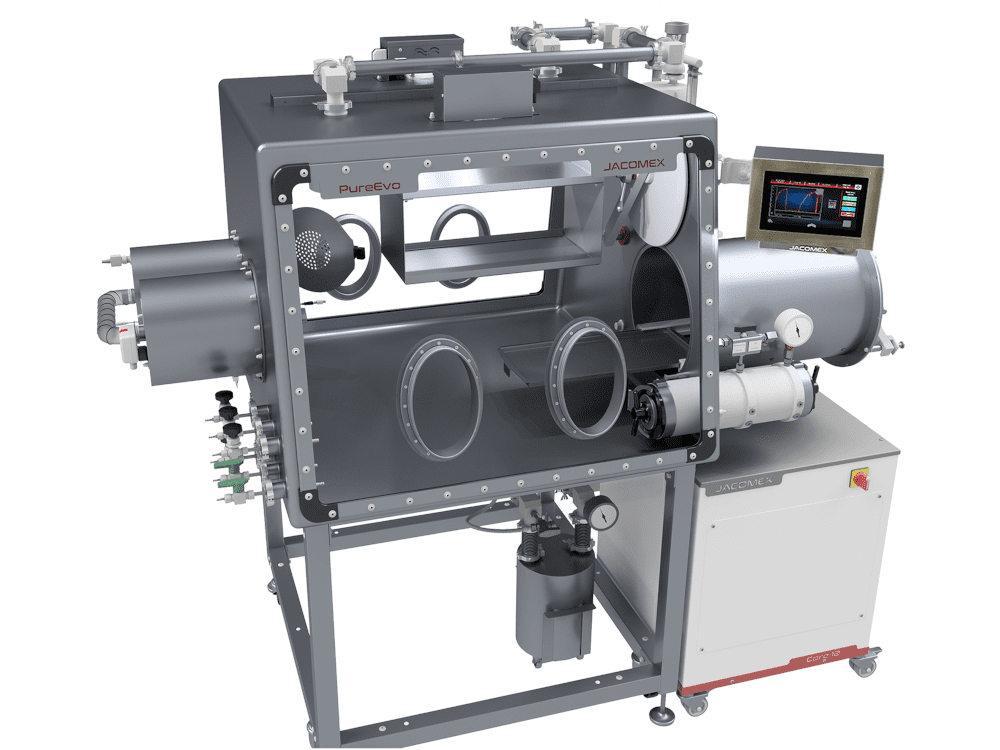

Jacomex designs special glove boxes and large volume containment enclosures that meet the requirements of additive manufacturing at all stages: argon containment of process machines and robots, gas management and recycling system allowing work at low levels in O2 and H2O, reconditioning of powders before process, post-process potting of parts and printing plates, storage and recycling of powders.

The enclosures developed by our R&D department and our design office in Lyon (France) have many advantages:

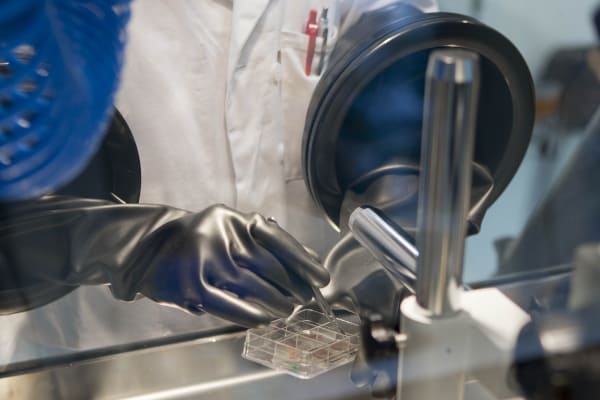

They ensure a secure containment of pyrophoric powders in a hermetic volume under a controlled atmosphere and form a protective barrier for operators and the environment.

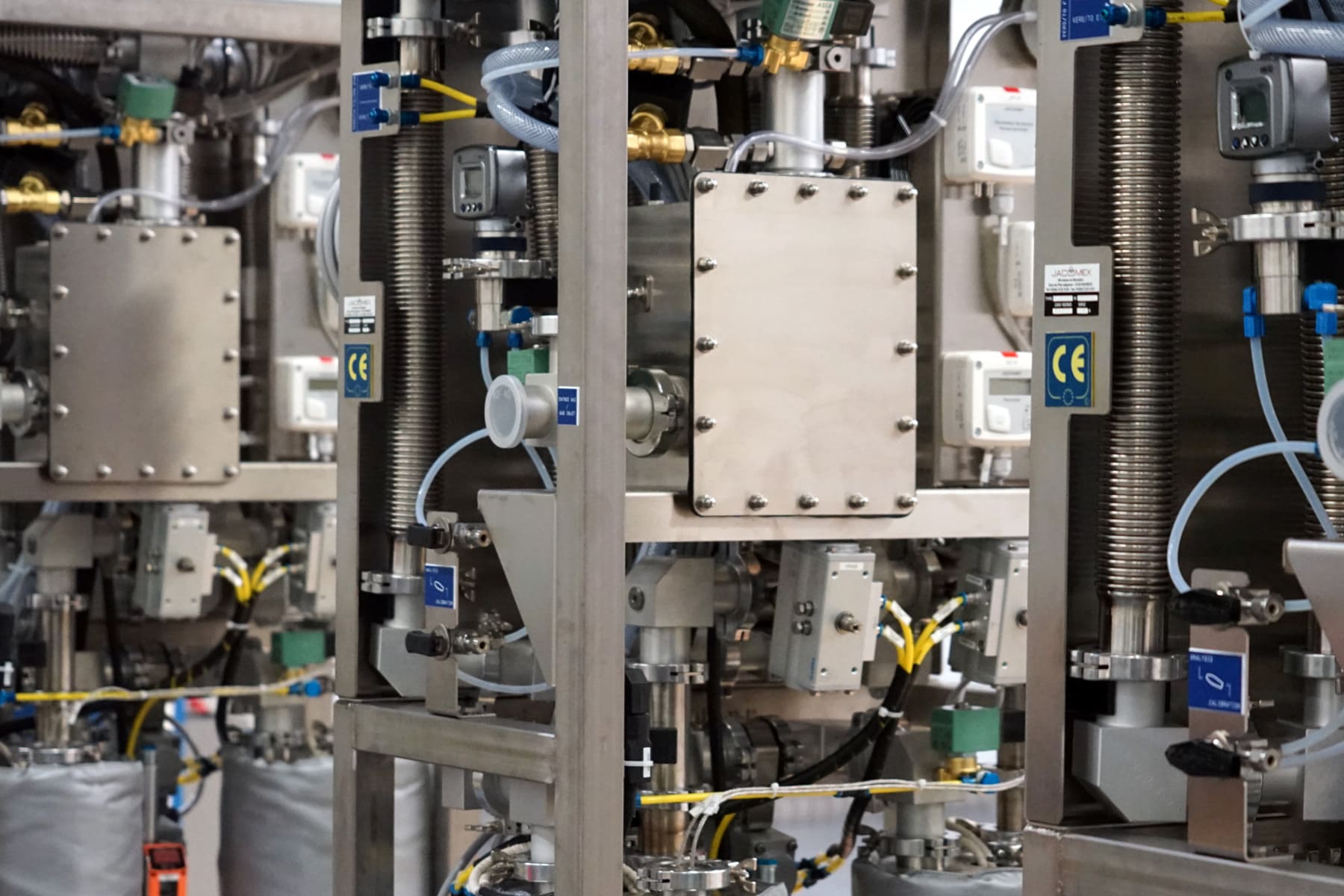

Many accessories or specialist equipment, argon purifiers, filtration units, and so on … optimize the operation of these containment enclosures.

Different Glove Boxes for Additive Manufacturing Application

They Trust Us

location

184 Avenue du Bicentenaire

Zone Les Prés Seigneurs

01120 Dagneux – France

Made in France

All of our products are designed and manufactured in France