Supporting healthcare innovation and productivity through technology

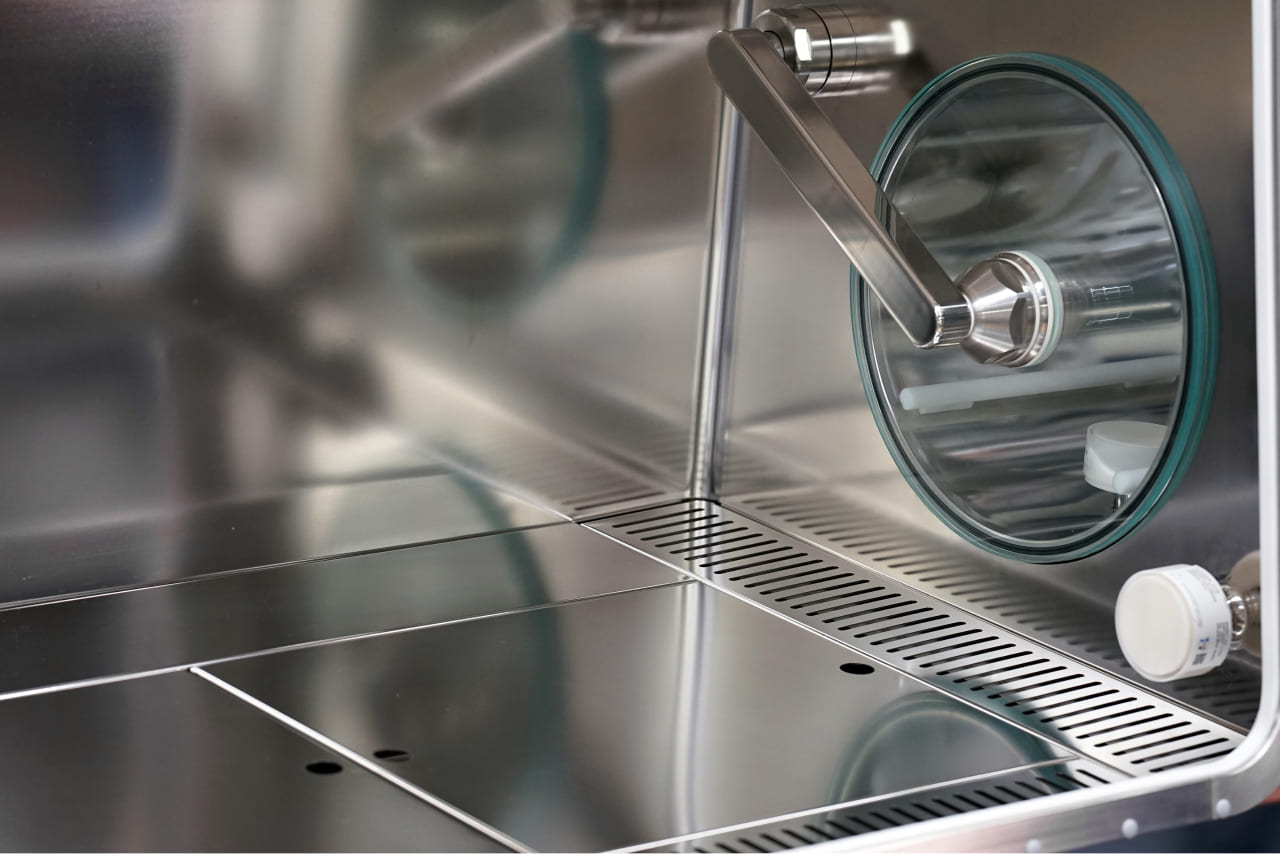

Expertise in containment isolators for nuclear and pharmaceutical safety

Jacomex is a French company, a French leader in containment isolators originating from decades of expertise in high integrity and sensitive applications for the Nuclear and Nuclear Medicine industries. Jacomex ’s embedded safety culture and innovative technologies drive our offer towards the design and development of operator and environment safety isolators, for pharmaceutical research and/or production processes.

- Potent Toxic And Cytotoxic Processes

- Highly Potent Active Pharmaceutical Ingredients (Hpapi & Api)

- Hazardous Liquids Processing

- Radiopharmaceutical

- Inert Gas Protected Processes

Standard configuration

Standardized Features For Cost Effective Modular Solutions

Base or optional:

- Standard 2, 3 or 4 gloveports and entry / exit airlock systems

- Front or side transfer airlock, interlocked

- Rounded internal corners

- Internal surface finish <0,6µm

- Hinged opening front panel

- Active confinement ventilation safety, mechanically and automatically activated

- HEPA H14or ULPA filtration

- ATEX Inside and outside the isolator

- Gas inerting down to less than 1ppm of O2 and/or H2O

Beyond The Standard For Turnkey Solutions

- Dedicated Jacomex project and engineering team

- Third party process and OEM integration

- Design validation 1:1 scale mock-ups

- OEB 4-5-6 certification

- IQ/OQ Documentation

- Data and controls GAMP5 batch reporting compliant with 21 CFR part 11

- HMI dedicated program fitting URS and regulatory requirements

- Alpha, Beta, Gamma, Neutron radiation shielding

- Acids resistant coatings (ALAR)

- Active confinement safety for containment breach protection

- Special filtrations: Acids, iodine, gases…

- cGMP design in compliance with the latests regulations

Exclusive Gas Purification For Oxygen Sensitive Medicines

Engineered bacteria drugs

Jacomex offers a unique Isolator design coupled with its exclusive inert gas purification systems to allow for the control of your isolator’s inner atmosphere

- Gas inerting down to less than 1ppm of O2 and/or H2O,

- Temperature control

- Relative humidity from 1ppm to 80%

- Oxygen levels from 1ppm to 20%,

Equipment and features

Recommanded accessories for pharmaceutical and medical applications

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG