Aseptic Containment Isolator – Definition

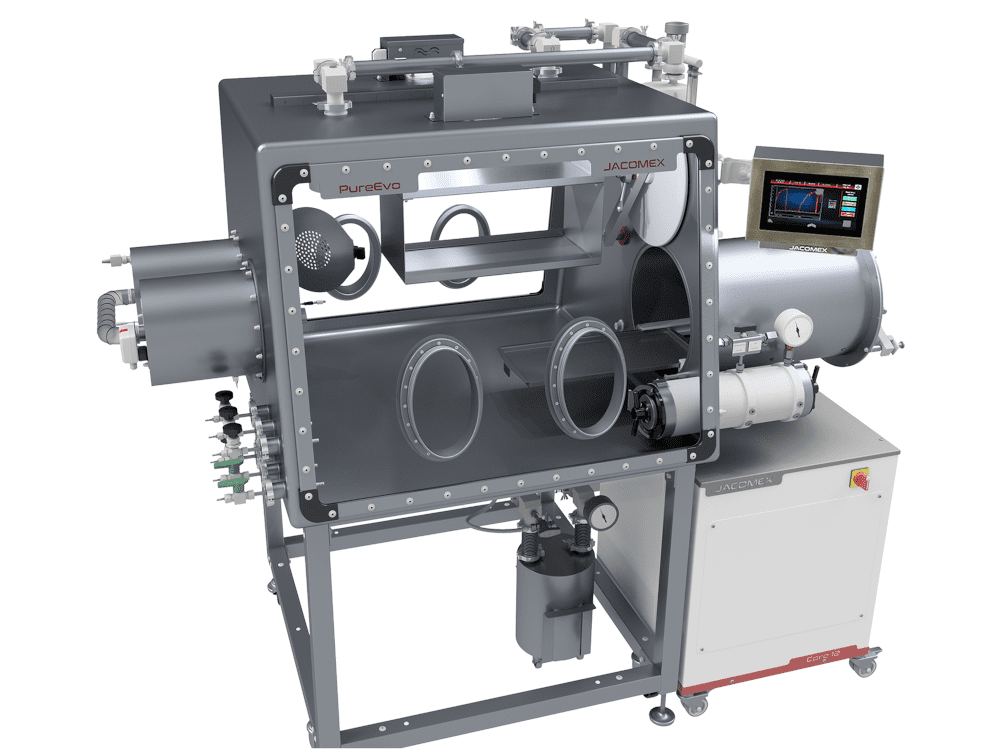

An aseptic preparation containment isolator provides a safe atmosphere and a high level of protection for aseptic preparations. The isolator is fitted with gloves on the walls and allows products to be stored, packaged or handled in the fully aseptic main chamber. The removal and introduction of products and the disposal of waste is done from the transfer systems integrated in the isolator.

Various models of isolators can be found on the market, with the equipment having the sole purpose of preventing any risk of contamination, protecting personnel during aseptic preparations and ensuring that the products handled are kept contained. The equipment can also be used for different applications such as advanced therapy drugs, dosing and weighing operations, etc.

In order to provide a hermetically sealed and contained work area, ensure proper operation and guarantee reliable containment, the isolator must have the following general characteristics:

- Just-in-time operation with or without internal storage;

- Positive or negative pressure;

- Laminar, turbulent or unidirectional flow ventilation;

- Side-by-side or facing workstations;

- HEPA or ULPA filtration;

- Fully secured transfer systems.

Specific elements can also be integrated within the isolator depending on its purpose. It is possible to integrate laboratory equipment (precision balance, incubator, centrifuge, etc.) or equipment specific to the pharmaceutical field.

Jacomex Isolators

Jacomex is world-renowned in the manufacture of containment isolators and glove boxes for various applications. Our qualified personnel and our design office can use the most efficient means to implement your project. We have developed different equipment to meet all your needs: gas purification and management systems, glove boxes, containment isolators for aseptic preparation, etc. We can offer you modular, customized or standard equipment, in accordance with your specifications and the strict constraints of your processes.

All of our isolators, used in the manufacturing stages of your products or for product research and development, are custom-made. For each project, our specialists provide personalised project management and technical support, with 3D simulations, factory acceptance tests (FAT), mock-ups and on-site acceptance tests (SAT). The design of the containment isolator for aseptic preparation complies with the requirements of the directives, the most stringent practices and the cGMP standards. You will be accompanied by our consultants and engineers in the definition of your equipment, taking into account sanitary constraints, your internal processes and your specific needs.