Purification Units for Controlled Atmospheres

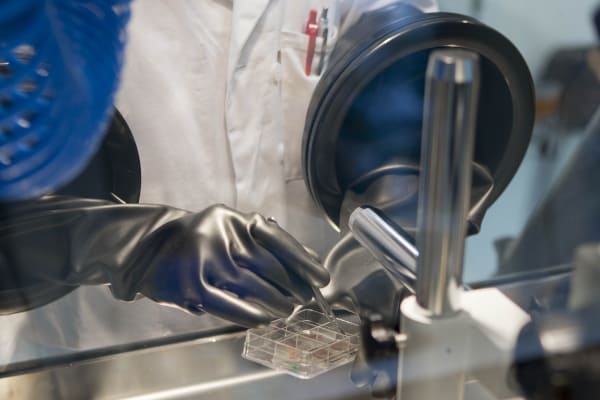

Elimination of H2O and/or O2 from Neutral Gases (Ar/N2/He)

JACOMEX systems have unique technical specifications which ensure long-lasting maintenance of purity with regenerations spaced out over time.

- Substantial gas savings

- Automatic regeneration (N2-Ar mix.3-10% H2)

- Stable purity over time without regeneration or maintenance

- Automatic pressure regulation without vacuum pump (including in use)

- Silent operation (noise level <50dB)

Shared technical data

|

|

|

|

|

|

|

|

|

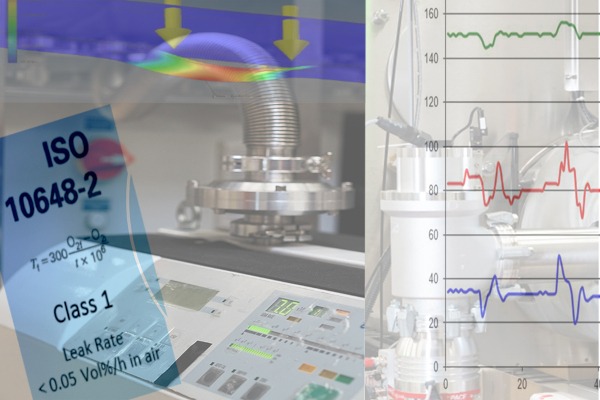

Expertise

Gas Purification and Management

Jacomex expertise allows us to answer your specific needs while taking critical parameters into account:

- Volume, number of gloves, glove box leak rate

- Internal process, materials and products handled.

- Application field, research, production

- Risks analysis and security constraints

- Running and maintenance costs

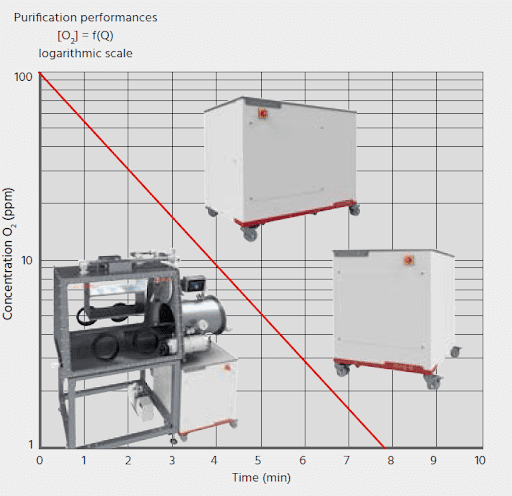

Range of gas purifiers

Single-line Purifiers

CORE-8

- Circulation flow: 90m3/h

- Capacities: 36L O2 – 1250g H2O

CORE-10

- Variable circulation flow: max.120m3/h

- Capacities: 45L O2 – 1250g H2O

CORE-12

- Variable circulation flow: max.120m3/h

- Capacities : 55L O2 – 1500g H2O

Double-line Purifiers

CORE-24P

- Variable circulation flow: max.120m3/h

- Capacities: 110L O2- 3000g H2O

- Avantages: Continuous purification, ready-to-use purification tank

CORE-24S

- Variable circulation flow: max.120m3/h

- Capacities: >280L O2 – 3000g H2O

- Avantages: boosted capacities, purification of large volumes, safety for oxygen-highly-sensitive processes

Custom Gas Purification Units

Standard Modular Purification Units

Four-models reactors that can run as independent or combined

modules:

- Recommended for large volumes and G[mega] glove boxes

- By-pass line and automated analysis circuit

- Air or water exchanger

P(SYS)-IV-P – Two double purifying lines

Technical Data

- Purification of volumes until 20m3

- Two parallel lines (4 purifiers)

- Continuous purification even during purification phases

- Capacity per line > 560L O2 – 3900g H2O

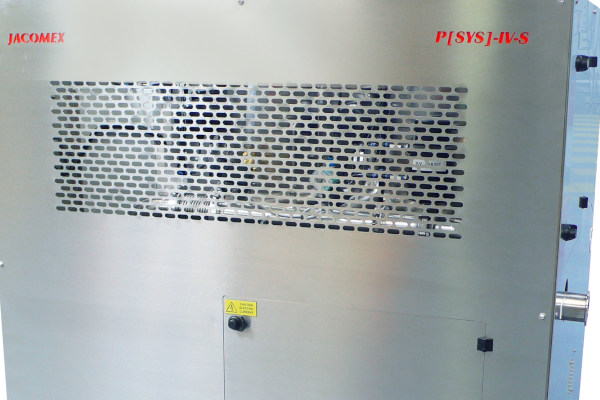

P(SYS)-IV-S – Two double purifying lines

Technical Data

- Purification of volumes until 40m3

- Two lines assembled in series (4 purifiers)

- Over-boosted H20 and O2 purification capacity

- Total capacity > 1120L O2 – 7800g H2O

They Trust Us

location

184 Avenue du Bicentenaire

Zone Les Prés Seigneurs

01120 Dagneux – France

Made in France

All of our products are designed and manufactured in France