How do Pharmaceutical Isolators work?

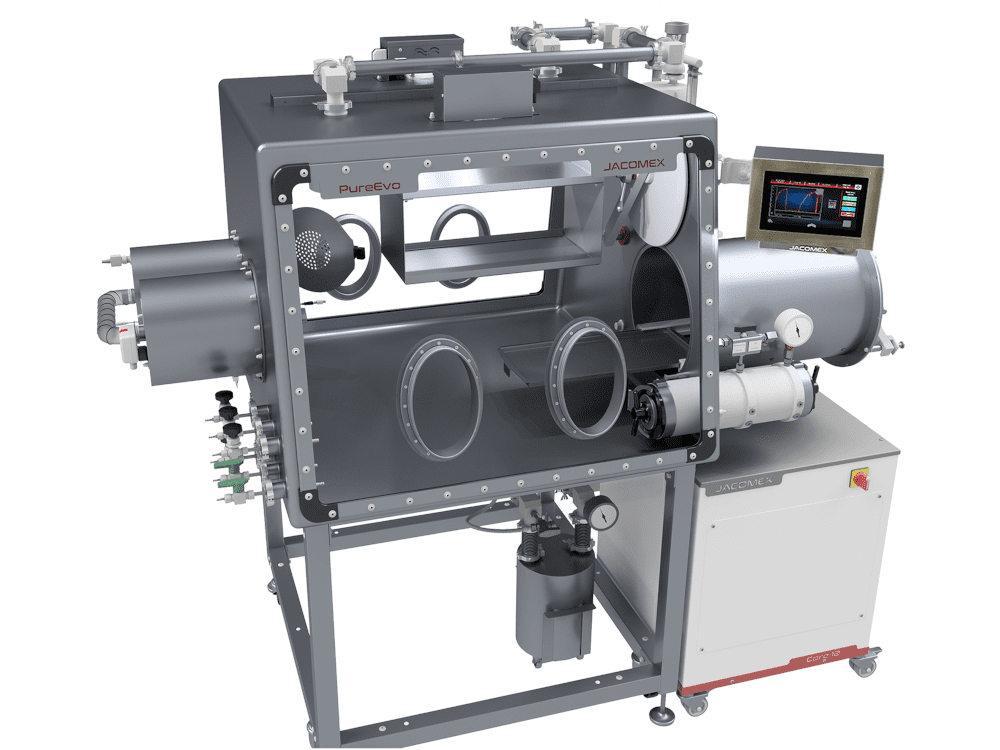

The pharmaceutical isolator is a bacteriologically sealed enclosure used in the medical and pharmaceutical environment for toxic processes and aseptic filling process. It is made of a perfectly sterile main isolator where the products are handled, stored or packaged using shoulder-high gloves placed on one of the walls. It also includes transfer systems that allow the entry and exit of the products and the elimination of waste without breaking aseptic conditions.

The pharma isolator is designed to meet two essential requirements:

- Containment

In production sites, an isolator allows the containment of pharmaceutical processes. They require a protected environment, free of viable microorganisms. The isolator ensures the production area and the personnel/environment are separate. Its role is to prevent contamination from one area spreading to the other. This technology provides a higher level of containment than the traditional clean room and uses an integrated decontamination system.

In general, the isolator is decontaminated by a sterilizing gas: hydrogen peroxide or H202. It uses very high efficiency filters for maximum product protection. These systems aim to eliminate microbes and particles from all possible sources of contamination such as the external environment and operators.

- Product transfer

Even when products are introduced into the enclosure or extracted from it, containment must be maintained and the atmosphere must be preserved from any contamination. This is where the transfer lock comes in. This system simplifies not only the transit of products and materials, but also the evacuation of waste, thus ensuring that the asepsis of the environment is always respected. Isolators for the pharmaceutical industry must comply with the class A Standards as outlined in the EU GMP Classification OJ 07/01/97.

The isolator can be equipped with many optional accessories such as hooks on docking bars, welders, cooling trays, cleaning accessories…

- Applications of a Pharma Isolator

There are many applications of an isolator for the pharmaceutical industry, mainly for production and control purposes. For example, it is useful when handling, transferring or packaging solid, semi-solid or powder pharmaceuticals, or handling and filling solutions and infusions. It is also used for sterility testing, defiltration, drying and weighing of cytotoxic principles, aseptic handling of tissues or biological production systems or pathogenic samples, etc. It can be used for the production and control of drugs and pharmaceutical products.

In the medical-pharmaceutical industry, the sterile manufacturing process must be carefully observed. Non-sterile pharmaceutical products pose serious risks to patients. Failure to follow the validated process can affect product quality and adversely affect patient and staff safety.

In addition, personnel must be protected from high-risk manufacturing processes, especially if they are working with highly active pharmaceutical compounds (High APIs). Protection is mandatory when the products, agents or active ingredients used present health hazards. In these cases, the use of more effective protective devices such as the pharma isolator is recommended. What are the reasons for this?

- Its decontamination system is more efficient.

Gas sterilization allows surfaces to be treated in a controlled environment, thus limiting particulate and microbiological contamination.

- The air treatment system guarantees optimal particle cleanliness.

An isolator for the pharmaceutical industry also integrates air treatment and filtration systems. They renew the air inside the chamber. Pre-filters at the inlet and filters at the outlet remove particles, microbes or other elements that could break the asepsis with greater efficiency.

- Internal conditions can be set and easily controlled.

All controlled atmosphere areas, such as isolators and glove boxes, are equipped with controllers. These systems allow the control, monitoring and tracking of the atmosphere conditions, including pressure maintenance, temperature control, humidity control, etc.

What are the Advantages of Pharmaceutical Isolators?

A pharmaceutical isolator is a modern medical technology that has several advantages for the pharmaceutical industry. It offers a superior sterile environment compared to conventional environments such as sterile clean rooms. Positive or negative pressures inside the chamber prevent contamination of the operator or the external environment in case of abnormalities. It ensures long-lasting sterility in accordance with pharmaceutical regulations. It is particularly effective during aseptic processes, procedure validations, sterility tests, etc.

The various controls and monitoring are facilitated due to the integrated options and software. Setting and recording of temperatures, pressures, humidity levels, etc. are possible, as are leakage and sterility controls. The data collected will be useful during inspections by the regulatory authorities.

An isolator for the pharmaceutical industry reduces costs. The equipment takes up less space, reduces possible refurbishment costs. They are cheaper to maintain and service, and that means lower operating costs.

Jacomex can design and manufacture pharmaceutical isolator that perfectly meets your needs by opting for a custom-made equipment. The device, options and accessories delivered can match your exact process requirements.