Molten Salt and Small Modular Reactor Research (SMR) in Glovebox

In laboratories and pilot platforms, research into molten salts and small modular reactors (SMRs) requires precise control of the atmosphere, containment and traceability. We design glove boxes and controlled atmosphere enclosures that protect operators and stabilise critical parameters when working with molten salts, materials and experimental loops dedicated to SMRs.

Main applications

Controlling O2/H2O for molten salt chemistry

The presence of oxygen and moisture disrupts the redox balance, accelerates corrosion and degrades measurements. Under negative pressure, the glove box confines risks, while loop purification maintains low O2/H2O levels. This combination of confinement and purification guarantees cleaner reactions, more reliable data and reproducible laboratory procedures.

Radiological confinement and R&D on SMR

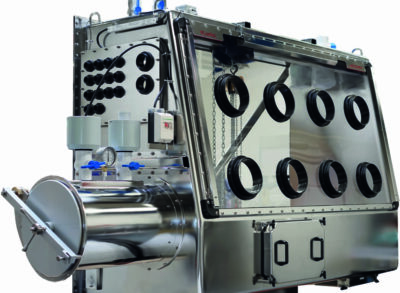

SMR campaigns combine thermophysical and electrochemical testing with the handling of sensitive materials. Containment protects the operator, limits releases and allows the integration of transfer locks for introducing crucibles, electrodes and instruments without breaking the seal. Smooth surfaces and quick-connect fittings facilitate cleaning and decontamination, reducing downtime.

Our solutions for research on molten salts and small modular reactors (SMRs)

We configure each workstation according to the type of salts (fluorides, chlorides), target temperatures, utilities and instrumentation. Three lines meet the needs of sample preparation through to test loops.

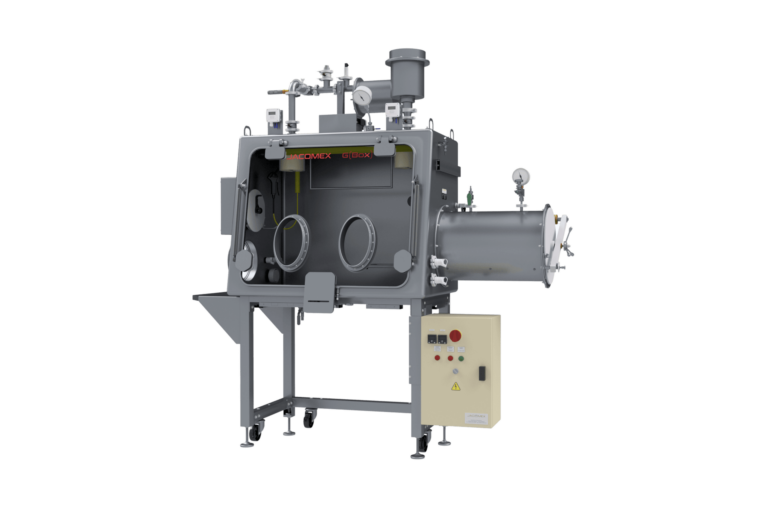

Gsafe for preparation and packaging

- Negative pressure containment workstation, ideal for weighing, drying and primary packaging of salts.

- High-efficiency filtration during extraction and clear instrumentation for repeatable operations.

- Airlock and accessory options for consumables and waste, with ergonomics designed for frequent use.

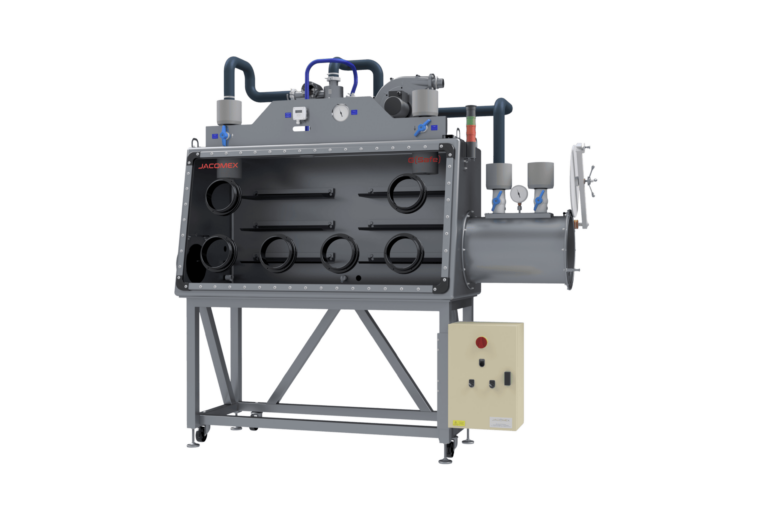

Gbox for complex processes and experimental loops

- Modular platform with adjustable length and number of bays, customised interfaces.

- Integration of feedthroughs for sensors, cable glands, rotary drums, balances and handling tools.

- Compatible with transfer chains for high-throughput testing, sampling and reconditioning.

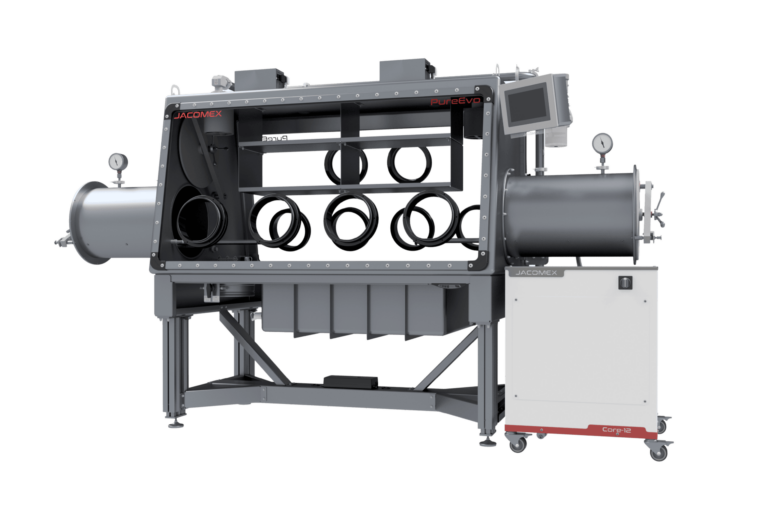

PureEvo for an ultra-stable O2/H2O atmosphere

- Ultra-clean enclosure with loop purification and advanced O2/H2O control, suitable for hygroscopic salts.

- Promotes bath stability and measurement quality while protecting sensitive instruments.

- Accommodates analytical sensors and qualification protocols for robust metrology.

Instrumentation and traceability for your research milestones

We integrate pressure sensors, alarm recordings and leak tests to document each step. Traceability covers inputs, atmosphere parameters and control results. Continuous monitoring and quick filter change options support availability and ensure milestones are met.

Integration with laboratory equipment

We design the interface between the glove box and your furnaces, potentiostats, spectroscopes and transfer lines. Utility passages, electrical feedthroughs and handling devices are adapted to temperatures and maintenance constraints. The goal is seamless integration, controlled cycle times and a measurable reduction in exposure.

Use cases in molten salt and SMR research

- Drying, melting and pre-conditioning salts prior to testing.

- Sampling for chemical and radiological analysis with full traceability.

- Assembly and calibration of electrodes, sensors and loops in a controlled atmosphere.

- Reconditioning and sealing in suitable containers for intermediate storage.

- R&D on materials and coatings in the presence of corrosive salts, with operator risk mitigation.

Research on molten salts and small modular reactors (SMRs): why work with Jacomex

Our experience with glove boxes and controlled atmospheres in the nuclear and molten salt chemistry industries brings you safety, reliability and efficiency. The Gsafe, Gbox and PureEvo ranges cover the full spectrum of uses, from standard workstations to customised architecture, to make research on molten salts and small modular reactors (SMRs) a controlled process that serves your scientific and QHSE objectives.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG