Radioactive Waste Management in Gloveboxes - Controlled atmosphere

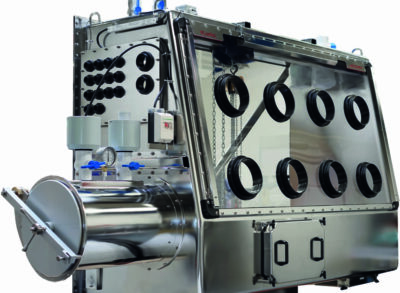

In laboratories and nuclear sites, radioactive waste management in glove boxes means combining safety and containment on a daily basis. At Jacomex, we design controlled atmosphere enclosures that enable waste to be collected, sorted and packaged while reducing operator exposure and environmental releases.

Main applications

Radioactive waste management in glove boxes: our principles

Our approach is based on two complementary barriers: a continuous physical barrier and a controlled atmospheric barrier. The glove box separates the operator from the waste, while negative pressure, appropriate filtration and transfer airlocks maintain containment. We design each station for stable negative pressure, appropriate HEPA/ULPA filtration and repeatable operations without breaking containment.

Why controlled atmosphere is a game changer

Controlling humidity and oxygen stabilises processes and limits unwanted reactions. During extraction, H14 filtration ensures particle retention, and purified recirculation, when required, supports internal cleanliness. The result: less cross-contamination, standardised procedures and more reliable measurement quality. This controlled atmosphere also reduces instrument wear and facilitates planned maintenance.

Safety, traceability and maintenance in operational conditions

We incorporate periodic leak tests, glove checks, pressure sensors and alarm recorders. Traceability is based on event logs and accessible indicators. Smooth surfaces, optimised internal radii and quick connectors simplify cleaning and decontamination. For flows, double-door airlocks, rotating drums or drum pass-throughs ensure entry and exit without loss of containment.

Radioactive waste management in glove boxes: our solutions

We offer three complementary lines. They can be configured according to your volumes, waste categories and on-site integration constraints.

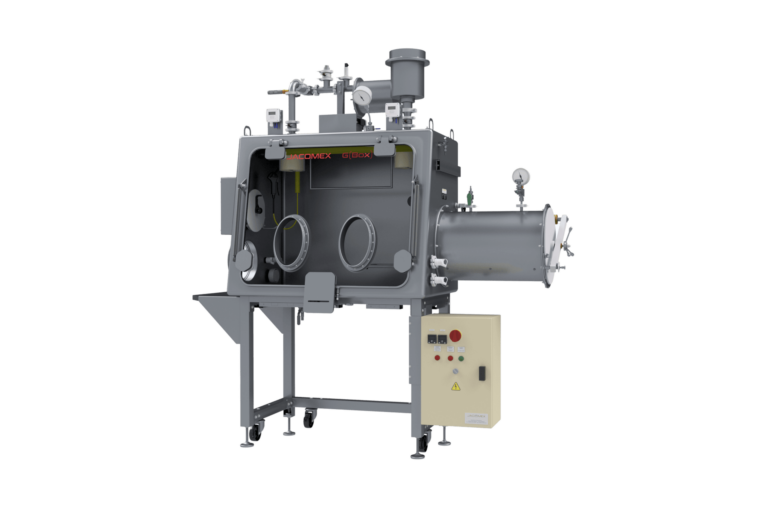

Gsafe

- Station dedicated to negative pressure containment, effective for sorting and primary packaging operations.

- High-efficiency filtration, easy-to-use instrumentation and careful ergonomics.

- Transfer lock options, internal bins and accessories adapted to repetitive movements.

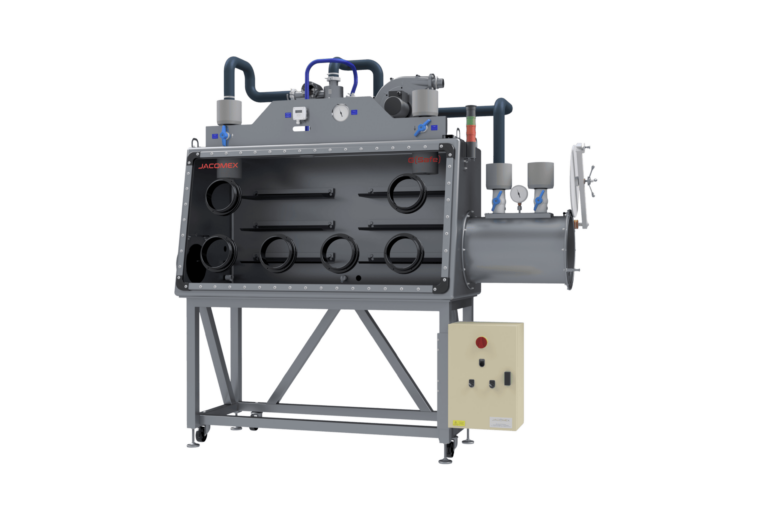

Gbox

- Modular platform for complex processes, customisable in terms of dimensions, interfaces and number of bays.

- Integration of drums, cable glands, scales, specific sensors and handling tools.

- Compatible with transfer chains for high-speed flows and scalable scenarios.

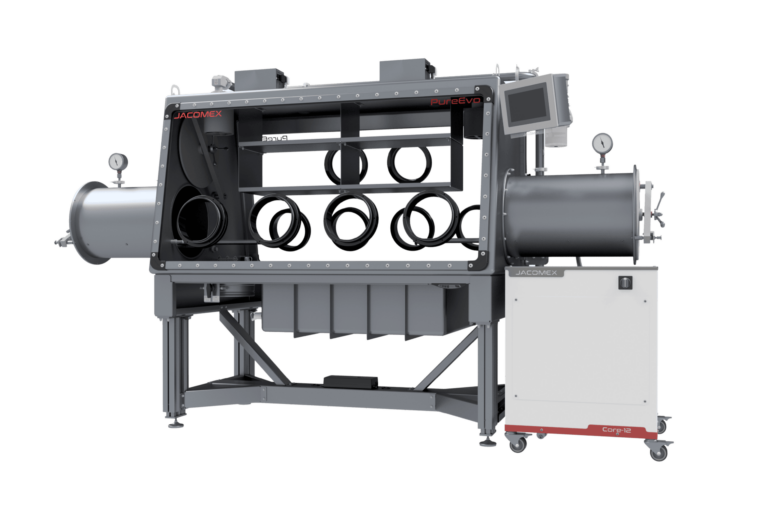

PureEvo

- Ultra-clean atmosphere enclosure with advanced closed-loop O2/H2O control.

- Suitable for sensitive waste or operations requiring superior stability and air quality.

- Easily accommodates analytical sensors, measuring devices and qualification protocols.

Integration with site processes and flows

We design the interface between the glove box and your hot cells, sorting lines, trolleys and containers. Waste classes, activity limits, prevention plans and QHSE requirements are integrated from the design phase onwards. Continuous monitoring and quick filter change options reduce downtime. The goal is high availability, controlled cycle times and a measurable reduction in exposure.

Radioactive waste management in glove boxes: typical examples of use

- Sorting and primary packaging of low- to medium-level solid waste, with sealing under containment.

- Sampling for radiological and chemical characterisation, with end-to-end traceability.

- Reconditioning of heterogeneous waste, light compaction, repackaging and labelling.

- Localised decontamination of small equipment before controlled release.

- R&D processes in a controlled environment when the atmosphere and containment impact safety and quality.

Support, qualification and sustainability

We provide engineering design, manufacturing, installation, qualification and support. Our teams work with you to define flow diagrams, select filter media and validate integrity tests. Sustainability is supported by available spare parts, service contracts and upgrades to keep pace with changing needs.

Radioactive waste management in glove boxes: why choose Jacomex

When you choose Jacomex, you benefit from proven expertise in glove boxes and controlled atmospheres for nuclear applications. Our Gsafe, Gbox and PureEvo ranges cover the full spectrum of needs, from standard workstations to customised architecture. We combine operator safety, containment quality and operational efficiency to make Radioactive Waste Management in glove boxes a reliable, traceable and optimised process that supports your QHSE objectives and productivity.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG