3D Printer (Additive Manufacturing)

Overview

3D Printer (Additive Manufacturing)

Description

Additive manufacturing or 3D metal printing has experienced rapid growth in recent years with numerous developments in the aeronautics, medical and automotive sectors.

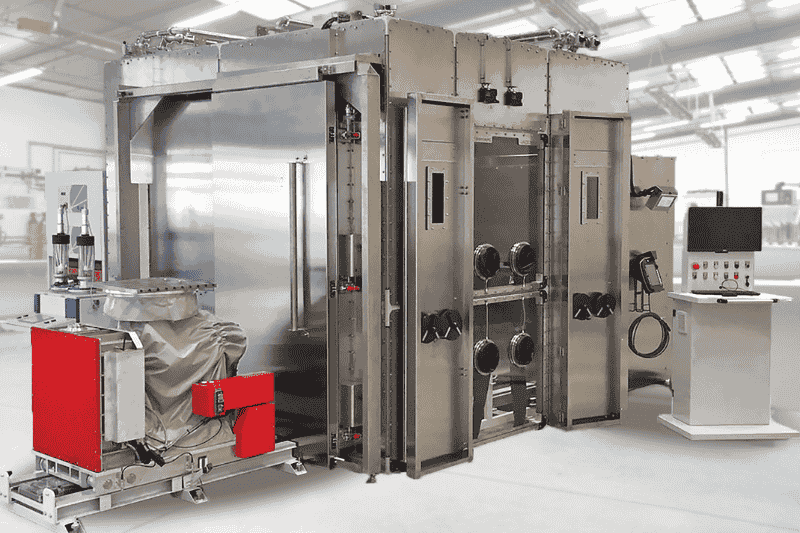

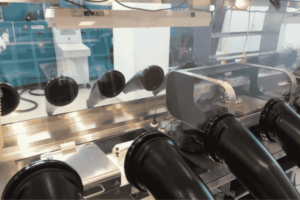

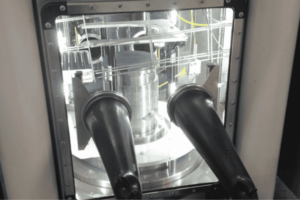

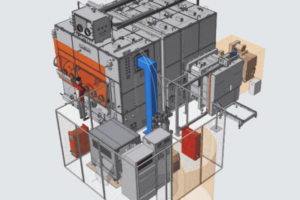

This technique has in fact made the cost-optimized manufacture of complex titanium parts possible as well as the surface functionalization and parts repairvia the deposition of metal filler materials based on superalloys. Regardless of the techniques used, WAAM (Wire Arc Additive Manufacturing), WLAM (Wire Laser Additive Manufacturing) or DED (Direct Energy Deposition), the powder deposition or laser powder coating processes must be carried out in an enclosure under a controlled atmosphere. . The enclosure (usually Mega) is connected to a closed-loop neutral gas (argon) purification system which allows control of the atmosphere at very low levels of humidity and oxygen (<1 – 10 ppm O2 and H2O ).

An enclosure with an integrated additive manufacturing machine has undeniable advantages such as operator and environmental safety, process safety (elimination of the risk of flammability/explosion of metal powders) by greatly reducing the oxygen level residual, real-time traceability, reproducibility of operating conditions, reduction of gas consumption and production costs.

Technical specifications - Information

|

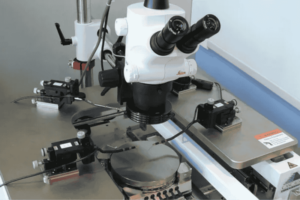

Custom 3D printer integrations

|

|

Tailor-made Gmega containment enclosure adapted to the process and the customer specifications

|

|

Large capacity argon purification unit allowing for the rapid and lasting elimination of residual oxygen in the neutral gas

|

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.

Equipment and Features

See our related products

Contact form

Need help or an offer? Contact us