Nuclear Process Integration in Glovebox

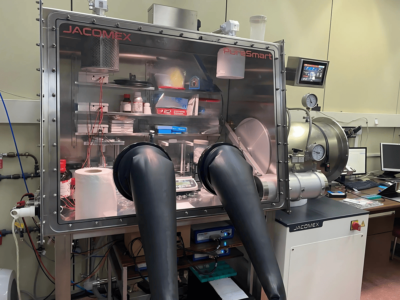

The integration of nuclear processes in glove boxes (Process Integration) is now a strategic issue for research centres, industrial facilities and players in the nuclear industry. It makes it possible to secure several stages of a complex process in a perfectly confined environment. Thanks to customised equipment such as that offered by Jacomex, it is now possible to optimise workflows while enhancing operator and environmental safety.

A concrete response to the constraints of nuclear processes

Reducing risks by centralising operations

Nuclear processes often consist of several successive stages: receipt of fissile materials, physical and chemical treatment, packaging and characterisation. Each of these stages must be secure. Integrating nuclear processes into glove boxes (Process Integration) allows these phases to be centralised in a single space, without breaking containment, thereby limiting the risk of cross-contamination or radioactive leaks.

Adapting the technical environment to specific challenges

Each process has its own requirements: some require maintenance under an inert atmosphere, others require constant negative pressure, flow monitoring or complex instrumentation. Containment solutions must therefore be modular, adapted to the size of the equipment, and offer optimal working ergonomics for the teams involved.

Equipment adapted to process integration

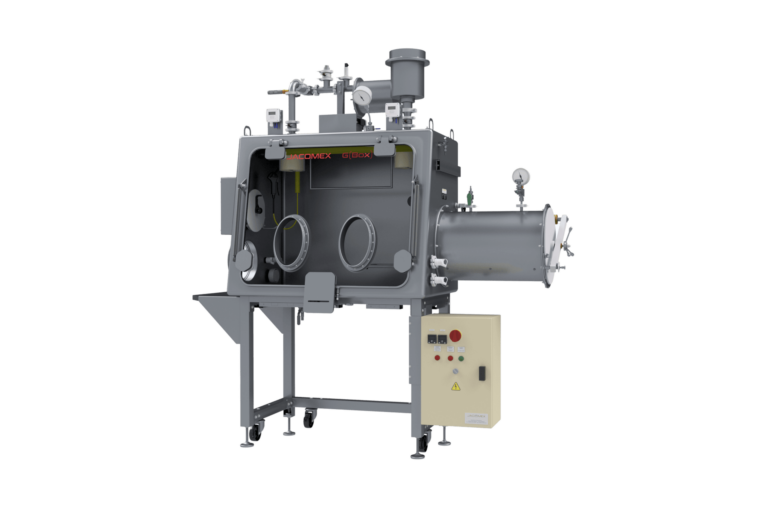

Gsafe: a secure solution for critical applications

The Gsafe model, developed by Jacomex, operates under negative pressure with filtered air, ensuring maximum operator protection. This model is particularly suited to the integration of sensitive processes, thanks to its robust structure, sealed walls and high-performance filtration system. It allows complete processing or packaging lines to be configured in a confined environment.

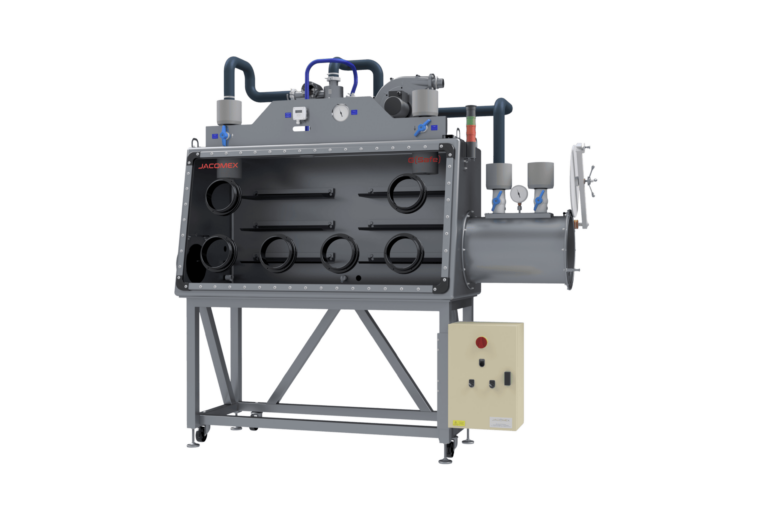

Gbox: a flexible system for scalable processes

The Gbox is designed to operate in both positive and negative pressure environments. This versatile model allows different stages of a nuclear process to be integrated into a single enclosure, while adapting the pressure according to the sensitivity of the product or the hazardousness of the substances being handled. Its modular design allows extensions, airlocks or specific equipment to be added at any time.

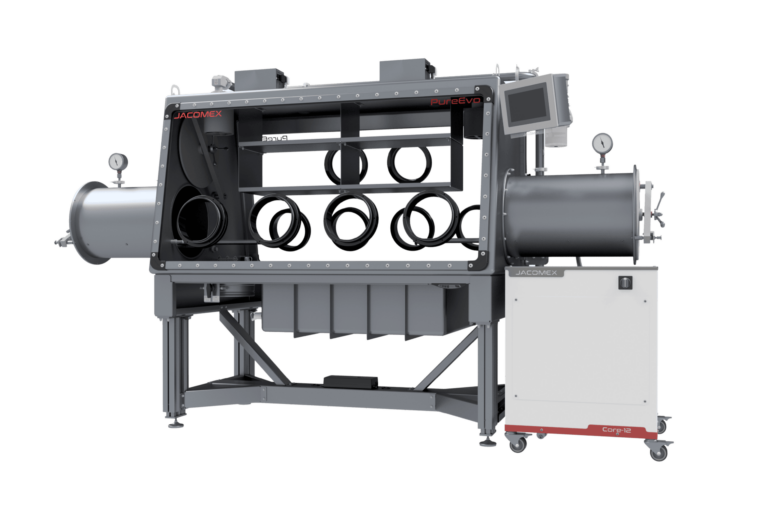

PureEvo: excellence for ultra-pure atmospheres

Certain nuclear operations require extreme atmospheric purity, particularly when working with materials that are sensitive to moisture or oxygen. The PureEvo glove box maintains a stable, purified environment with extremely low levels of moisture and contaminants. It is ideal for laboratories specialising in cutting-edge research and the processing of sensitive radioactive materials.

A design with the operator in mind

Ergonomics, comfort and productivity

Integrating several stages of a nuclear process into a single glove box should not be at the expense of ergonomics. Jacomex designs equipment that takes into account the working position, visibility inside the enclosure, ease of access to controls and comfort during prolonged use. The efficiency of our teams depends largely on the fluidity of their daily movements.

Scalable systems to support your projects

Nuclear projects evolve. Equipment must keep pace. The glove boxes we offer are modular, reconfigurable and interconnectable. They can be upgraded by integrating new instruments, adding transfer lines or connecting several enclosures together. This scalability is a strong asset for laboratories and sites undergoing constant change.

Jacomex, specialist in integrated nuclear containment

For over 75 years, Jacomex has been supporting major players in the civil and military nuclear industries in their most complex projects. We design, manufacture and install customised glove boxes to meet the specific needs of each process. We have extensive technical expertise, in-depth knowledge of standards and a strong capacity for innovation.

The Gsafe, Gbox and PureEvo models are the result of years of development and dialogue with users in the field. They are now deployed in many countries for nuclear research, the protection of radioactive materials and the treatment of sensitive waste. We also provide long-term maintenance, extension and adaptation of our equipment.

The integration of nuclear processes into glove boxes (Process Integration) is a key lever for securing, streamlining and modernising the most sensitive nuclear operations. By designing customised containment systems adapted to the realities of the field, Jacomex enables teams to work efficiently in a secure, ergonomic and scalable environment.

Contact us today to discuss your project and benefit from expert support in the design of your integrated glove box.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG