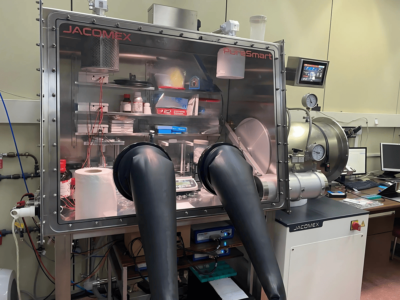

Mox Fuel Development and Fabrication in Glovebox

The development and manufacture of MOX fuel in glove boxes is a sensitive nuclear operation that requires a high level of technical expertise and safety. Due to the radioactivity of the materials used, all stages must be carried out in a confined and controlled environment. Jacomex offers solutions specially designed to meet the requirements of this sector, ensuring optimal containment and ergonomics adapted to each phase of the process.

Development and manufacture of MOX fuel in a glove box: a highly secure and standardised process

Working safely with fissile materials

MOX fuel (mixed oxide) consists of uranium dioxide and plutonium dioxide. It is used as an alternative to conventional fuel in nuclear reactors. Its manufacture involves the handling of highly radioactive substances, which requires the use of glove boxes with reinforced protection.

The development and manufacture of Mox fuel in glove boxes (Mox Fuel Development and Fabrication) relies on perfect control of containment, the internal atmosphere, decontamination and dust control. The aim is to protect operators and the environment and guarantee product integrity.

Rigorous management of each stage

There are many operations involved in the manufacture of MOX: receiving and weighing the powders, homogenisation, pressing, sintering, inspection and packaging. Each of these stages is critical. Containment must never be broken. Glove boxes must therefore be able to integrate machines, measuring instruments, conveyors and monitoring systems without compromising safety.

Three tailor-made solutions for a controlled process

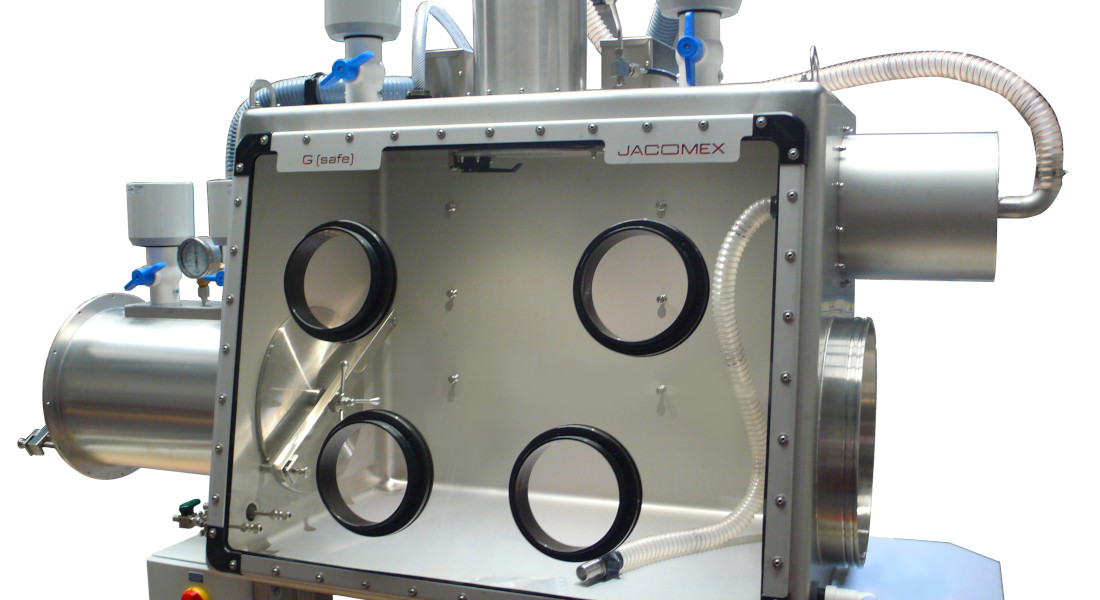

Gsafe: the benchmark for robust negative pressure containment

The Gsafe is a glove box designed to operate under negative pressure with absolute filtration, providing maximum protection for the operator. Its robust, modular design allows several stages of the Mox process to be integrated into a single continuous line.

Equipped with HEPA filters and atmospheric control options, Gsafe is a reliable model for working with radioactive or toxic powders. It offers excellent visibility and simplified access for maintenance operations.

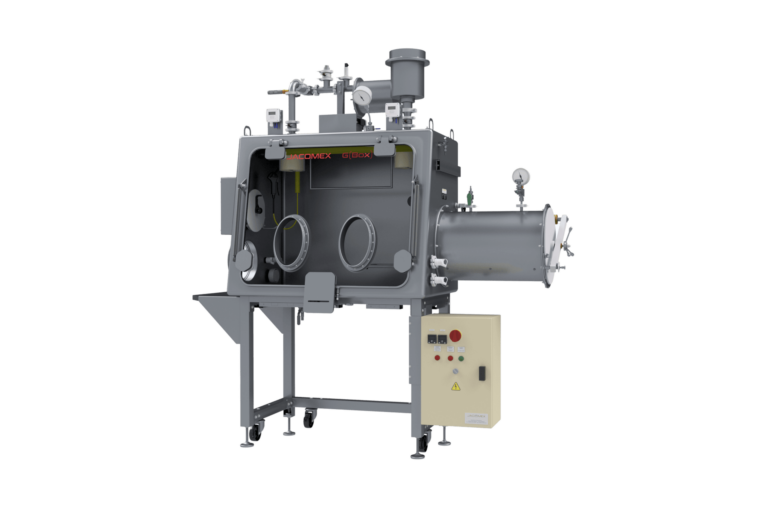

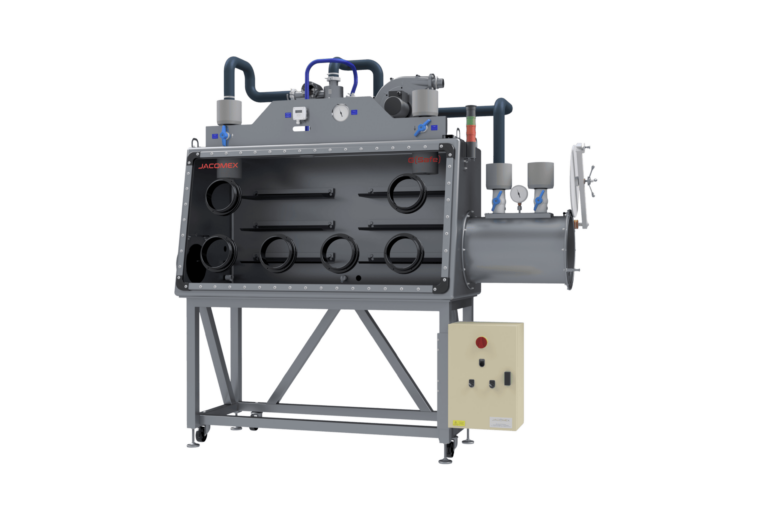

Gbox: versatility and adaptability in negative or positive pressure

The Gbox model can operate in positive or negative pressure, depending on the level of protection required. This flexibility is essential in a process as demanding as Mox fuel fabrication. It is therefore possible to adjust the type of containment according to the nature of the materials handled or the level of purity required.

The Gbox allows specific equipment to be integrated while ensuring that the entire system is completely sealed.

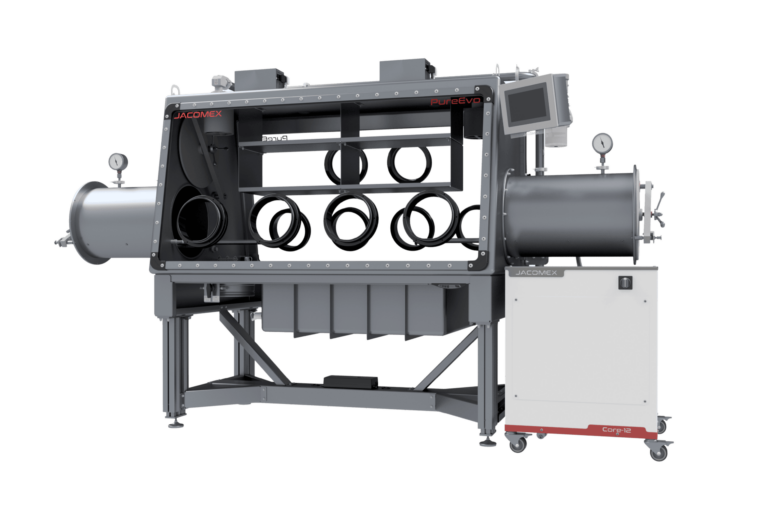

PureEvo: a solution for ultra-high purity environments

The PureEvo model is particularly suited to process stages requiring an ultra-pure environment (very low oxygen and humidity levels). It is ideal for R&D laboratories working on sensitive formulations or fuel behaviour studies.

Its advanced purification system maintains perfectly stable internal conditions, even during long handling times or complex operations.

Development and manufacture of MOX fuel in glove boxes: combining ergonomics and high technology

An approach designed for operators

In an environment as demanding as the nuclear industry, technical performance is not enough: workplace ergonomics are also essential. Jacomex ensures that each glove box model offers a comfortable, intuitive workstation that is perfectly suited to the duration and complexity of the operations.

This involves optimised equipment layout, seamless integration of control interfaces, maximum visibility inside the enclosure, and gloves suitable for intensive use.

Tailor-made support

Each project related to the development and manufacture of Mox fuel in glove boxes (Mox Fuel Development and Fabrication) is unique. We offer personalised support from the design phase onwards. Our technical teams work with operators, safety engineers and operational teams to build solutions that are perfectly suited to each site.

Digital models, flow simulations, integration tests and validation phases are carried out upstream to guarantee commissioning without compromise.

Jacomex, a trusted player in the nuclear industry

A recognised specialist in containment systems, Jacomex has been equipping laboratories, research centres and industrial sites in the civil and military nuclear sectors for several decades. The solutions we develop meet the most stringent standards in terms of radiation protection, particle containment and manufacturing quality.

All equipment is designed, tested and manufactured in France, with a constant focus on performance, durability and innovation. We also provide maintenance, modernisation and upgrading services for existing installations.

The development and manufacture of Mox fuel in glove boxes (Mox Fuel Development and Fabrication) requires advanced technical expertise, perfect control of containment and a design adapted to each stage of the process. With its Gsafe, Gbox and PureEvo models, Jacomex offers reliable, safe and sustainable solutions for the most demanding projects in the nuclear sector.

Contact us to discuss your requirements and work with us to design a tailor-made containment system.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG