Isolators for Pharmaceutical and Medical Applications

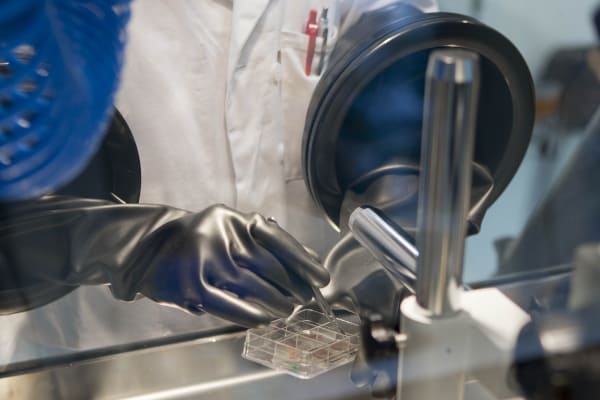

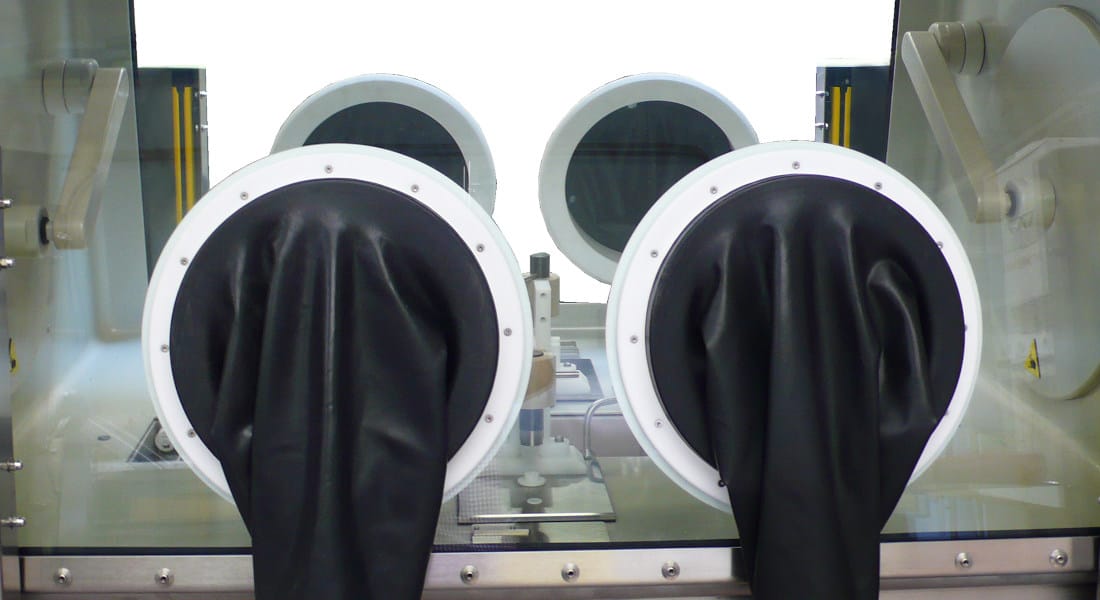

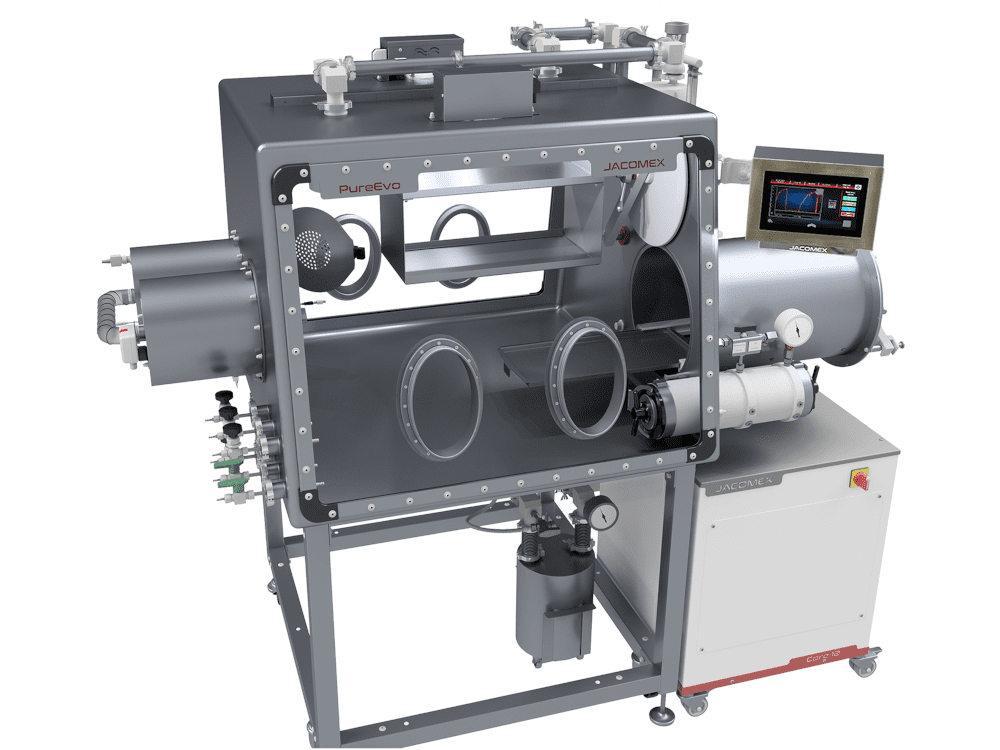

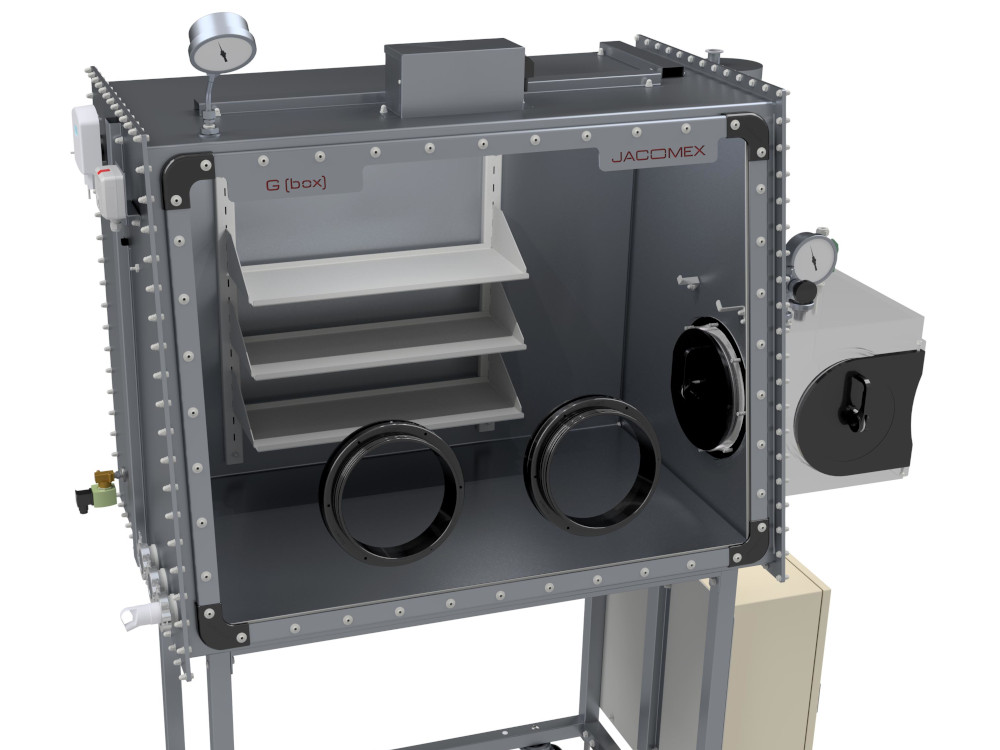

Jacomex offers a complete range of custom glove boxes and medical isolators for all kinds of specific applications in the medical sector requiring strict sanitary and environmental constraints. Uses can be found both in production e.g., in the assembly and packaging of implants, and in R&D e.g., in nanomedicine for the macromolecular synthesis and functionalization of nanoparticles or the characterization of surfaces grafted with bioactive polymers.

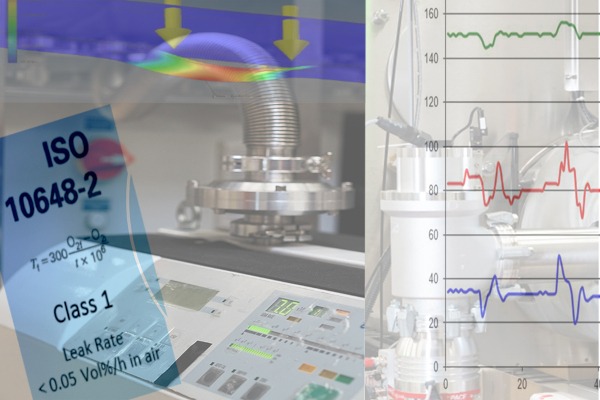

Jacomex has expertise in all the techniques that will be useful to comply with specific requirements, whether in terms of decontamination, disinfection, quality and specificity of the atmosphere required in the process. It is possible to eliminate microbial contamination and to control the level of particles to dust classes established according to the ISO 14644-1 standard. These ultra-clean media are obtained by means of laminar flow integrated directly into the glove box or isolator. Automation and regulation allow an atmosphere management adapted to all processes with humidity, oxygen and temperature control. Technical solutions have been developed especially for the medical sector and avoid the presence of carbon particles, traces of hydrocarbons and other pollutants.

Glove Boxes for Pharmaceutical and Medical Applications

Jacomex is the ideal partner in all stages of development and production of all types of medical devices: surgical and dental implants, bone or bio integrable prostheses, pacemakers and implantable automatic defibrillators made of titanium…

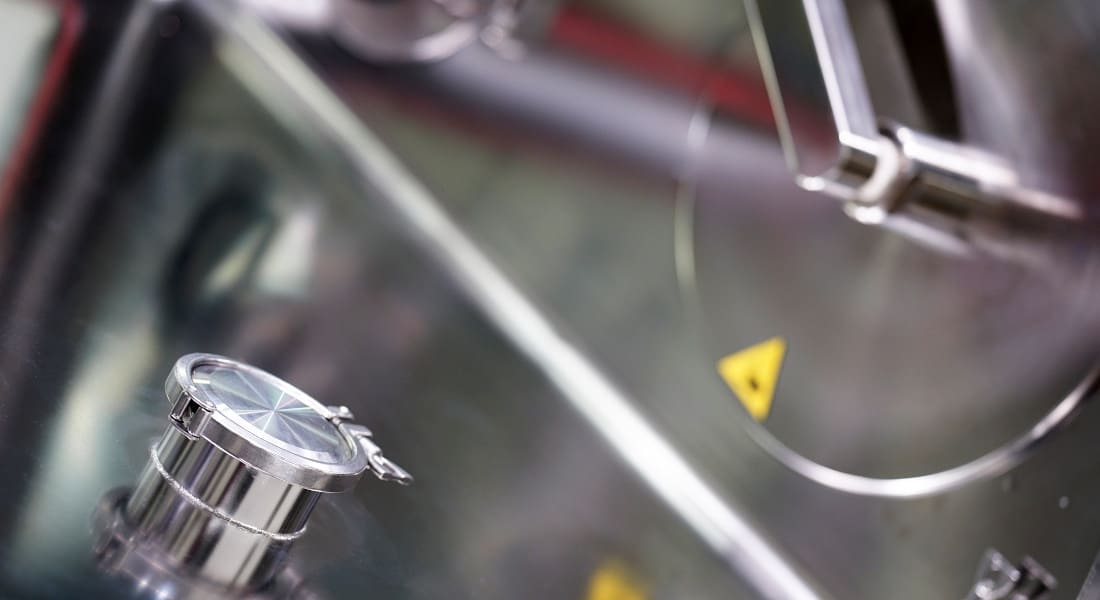

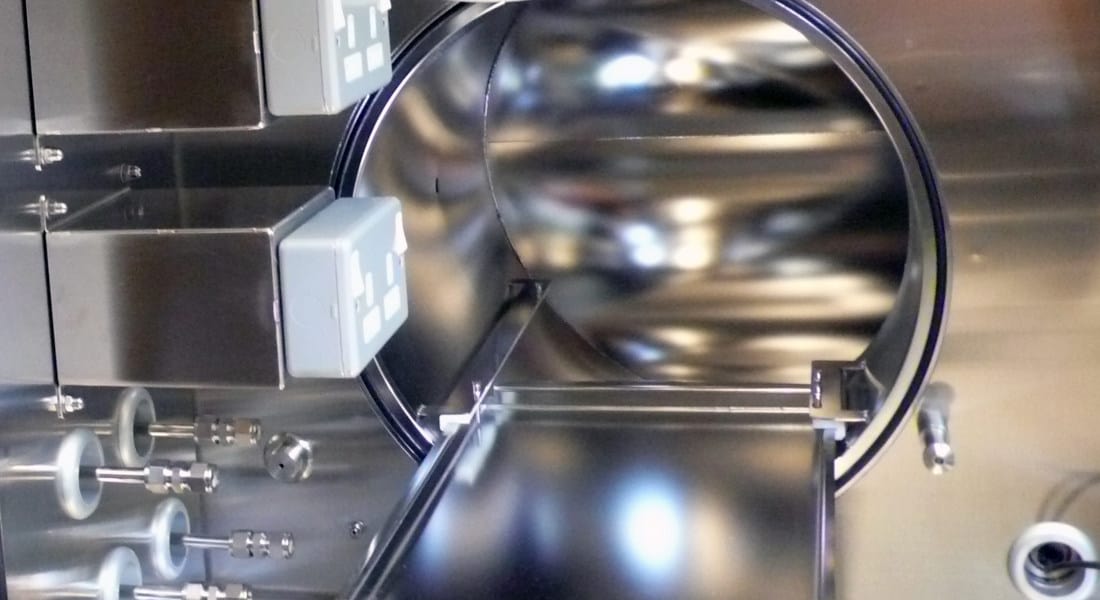

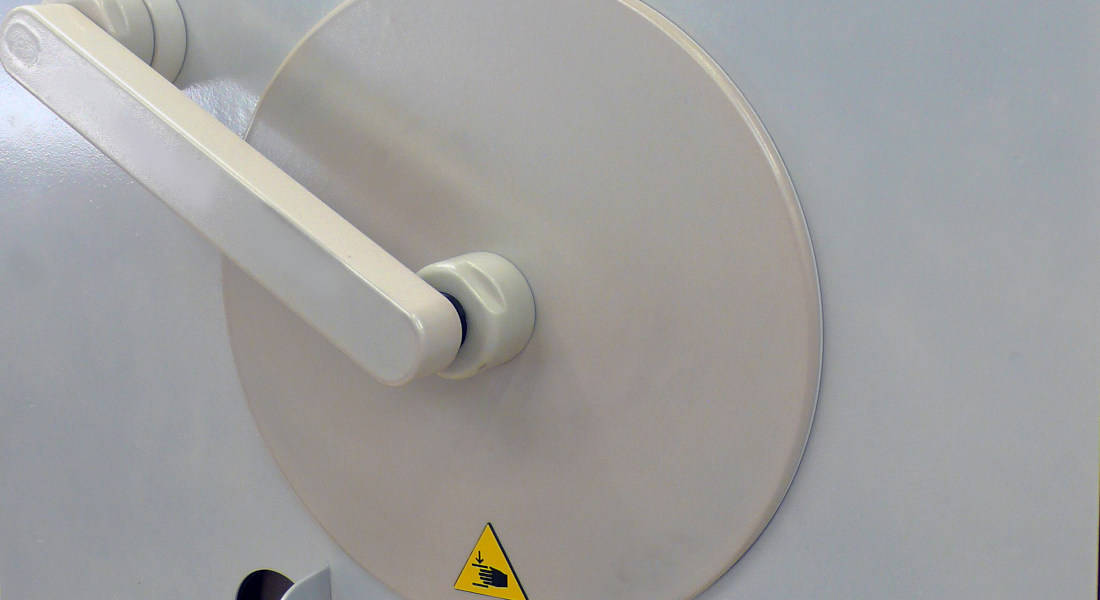

Our engineers design the entire internal part of the glove box with the utmost care because every detail counts and allows us to respect the URS (user requirements specifications) of our customers. The quality of the materials and the finish of the internal surfaces of the glove box or insulator are particularly important. If cleaning and disinfection are necessary, the internal surface roughness must be checked and validated (≤ 0,8 μm) to facilitate these operations. Identical to pharmaceutical isolators, our design office designs AISI 304L/316L stainless steel “monobloc” boxes, as well as special profile panel joints avoiding retention zones. All welds inside the box can be finished with degreasing, pickling and passivation treatments, which are necessary to bring the stainless-steel back to its original quality in terms of hardness and corrosion resistance.

For processes that can generate toxic or corrosive vapors (hydrochloric acid, sulfuric acid, etc.), we offer Teflon® or Halar® type coatings as well as filters and acid traps. For photosensitive ingredients, the installation can be equipped with inactinic lighting and work panels with UV protection.

Operation and ventilation: depending on the desired atmosphere, the glove box/isolator works in open or closed circuit. Sensors automatically regulate the pressure, hygrometry and/or oxygen level. H13 or H14 filters complete the containment of the workstation.

For the smooth running of the internal operations, all kinds of hermetic passages can be provided and allow to relay cleaning nozzles, nitrogen blowers, shower heads, peristaltic pumps, sodium chloride supply… Similarly, all the facilities, including sinks, gratings, effluent and solid waste evacuation, secure transfers, storage can be integrated in the respect of safety and ergonomics of the workspace.

A personalized project management accompanies each project with technical follow-up, 3D modeling, modeling, IQ-OQ, FAT and SAT receptions.

They Trust Us

location

184 Avenue du Bicentenaire

Zone Les Prés Seigneurs

01120 Dagneux – France

Made in France

All of our products are designed and manufactured in France