Inert Gas Protected Processes in Glovebox

In laboratories, pilot workshops and R&D lines, inert gas protected processes in glove boxes mean stabilising the atmosphere, securing operations and guaranteeing reproducibility. We design glove boxes that protect the operator and the product while maintaining low O2 and H2O levels for controlled reactions, preserved materials and comparable results from one campaign to the next.

Why inert gas changes process quality

Working under argon or nitrogen reduces oxidation, hydrolysis and unwanted reactions. With negative pressure for containment, combined with loop purification to keep O2/H2O low, your kinetics become more stable, your yields more consistent and your quality controls more reliable. This approach limits waste, protects active surfaces and extends the life of instruments.

Inert gas protected processes in glove boxes: parameters to be controlled without compromise

Three factors dictate performance: gas purity, residual O2 and humidity. We integrate O2/H2O sensors, flow meters, pressure controllers and continuous recording to track each step. Alarm thresholds and correction procedures allow action to be taken before drift occurs, without breaking containment. Repeatability comes from fine adjustment of flow rates, rigorous airlock management and simplified maintenance of filtration media.

Compliance, operator safety and maintenance

Containment protects people, equipment and the environment. We provide leak testing, glove testing, appropriate filtration and decontamination procedures in line with your QHSE requirements. Smooth surfaces, optimised internal radii and quick connectors simplify cleaning and maintenance, reducing downtime and improving availability.

Our solutions for inert gas-protected processes

We configure each workstation according to your chemicals, temperatures, integration constraints and instrumentation needs. Three lines cover the essentials, from sample preparation to complex assemblies and pilot series.

Gsafe for preparation and packaging

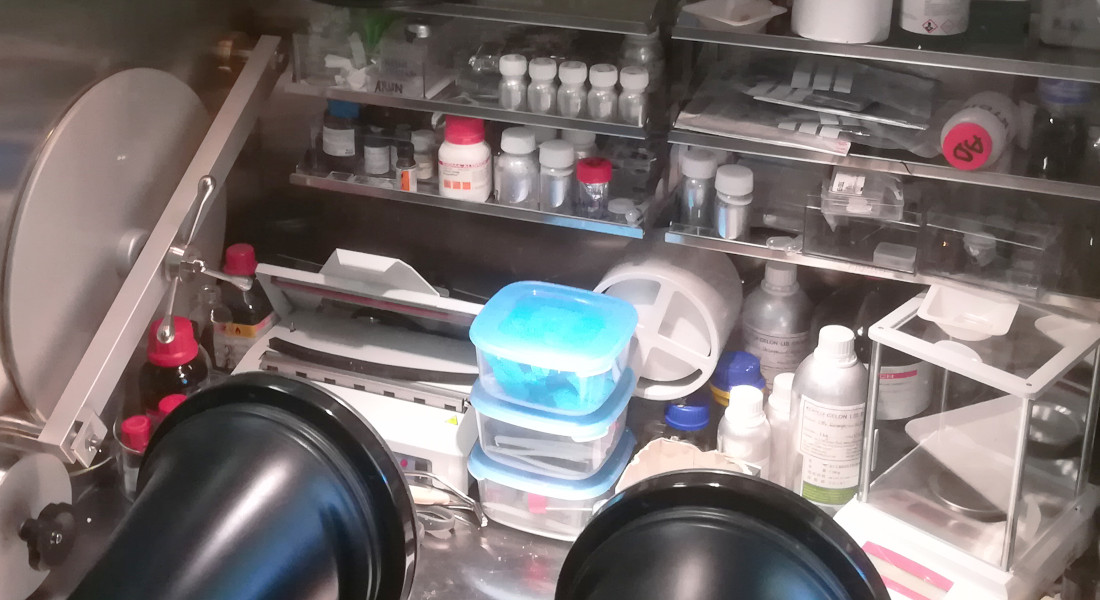

- Negative pressure containment workstation, ideal for weighing, drying, dissolving and packaging sensitive reagents.

- Clear reading of O2/H2O parameters, ergonomics designed for frequent movements and airlock options for consumables and waste.

- Excellent compromise between safety, ease of use and cost of use.

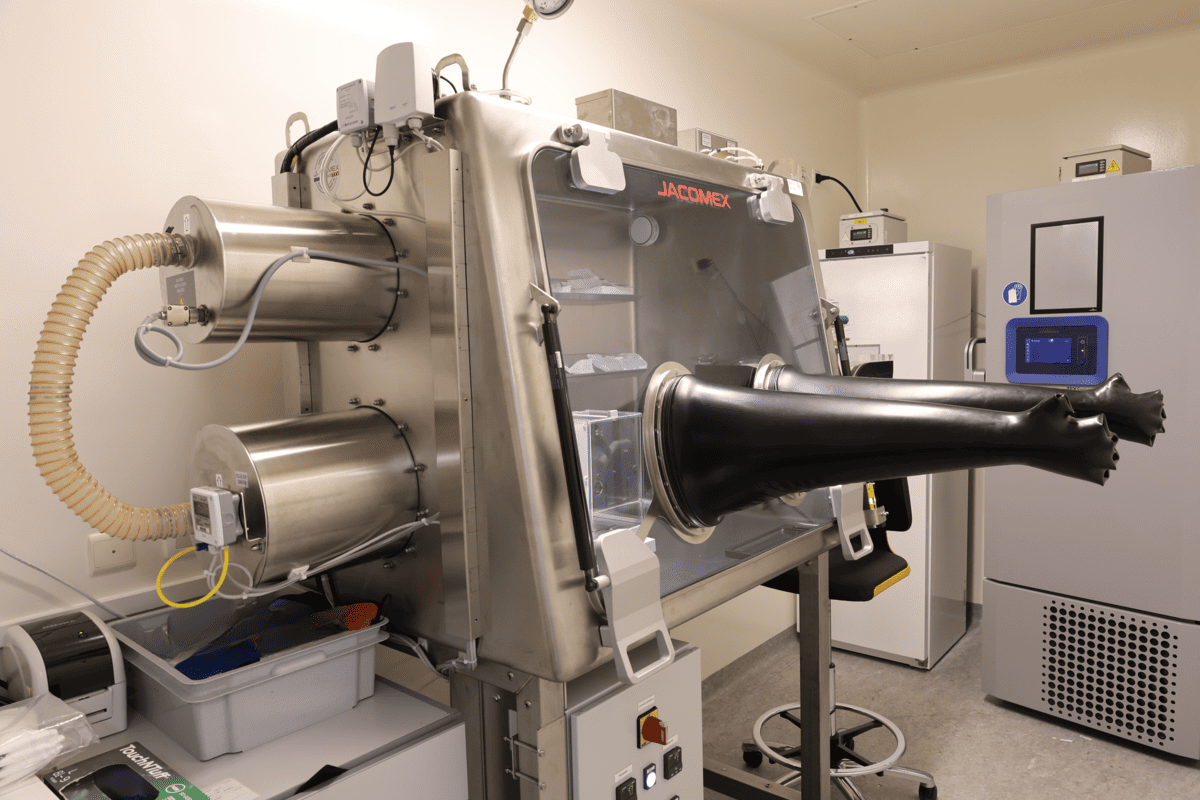

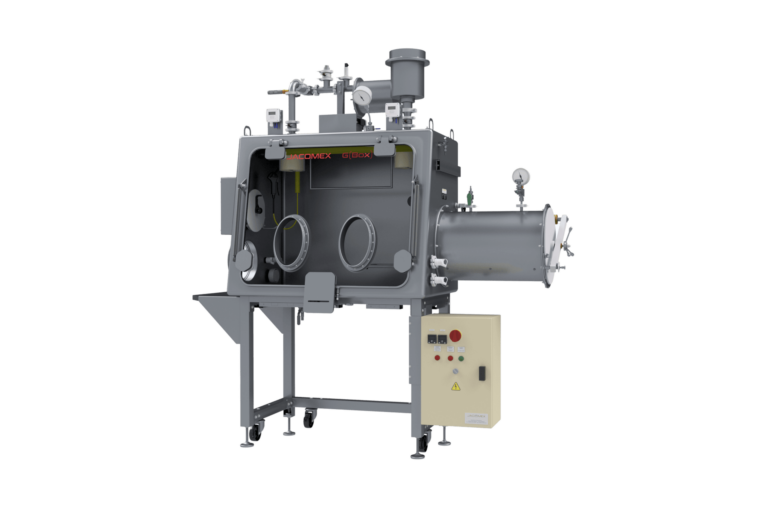

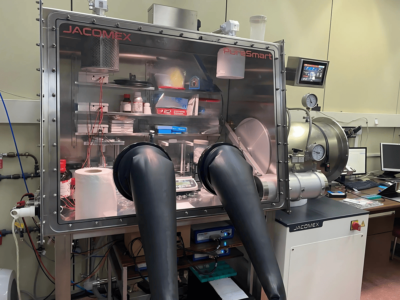

Gbox for complex processes and special integrations

- Modular platform with adjustable length and number of bays, customised interfaces.

- Integration of feedthroughs for sensors, cable glands, drums, scales, handling tools and ports for process lines.

- Compatible with transfer chains for high-speed flows, process development and small series.

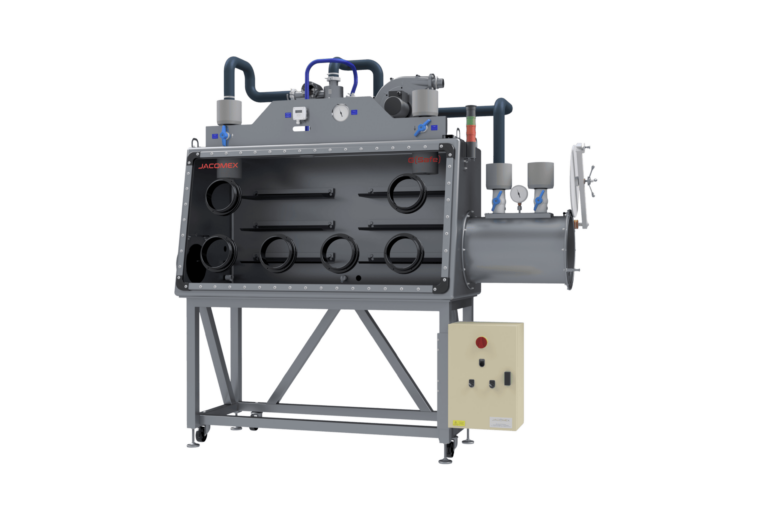

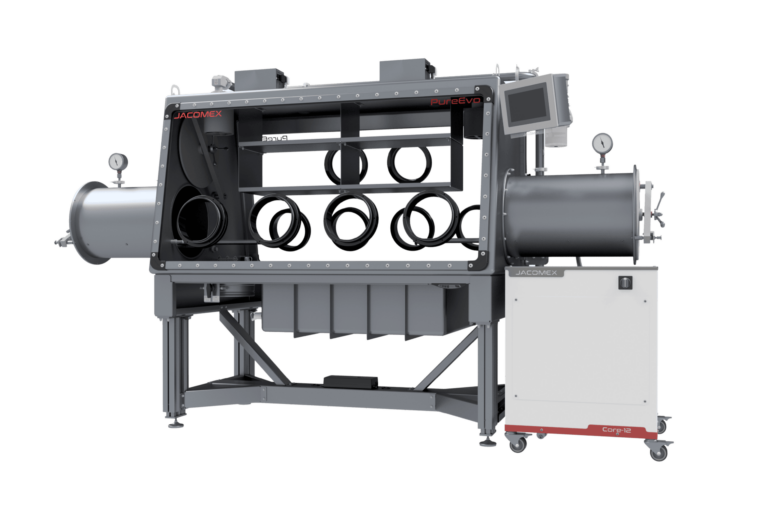

PureEvo for an ultra-stable O2/H2O atmosphere

- Ultra-clean enclosure with loop purification and advanced O2/H2O control for highly reactive chemicals.

- Promotes reaction stability, metrology accuracy and the durability of sensitive instruments.

- Easily accommodates analytical sensors and qualification protocols.

Inert gas protected processes in glove boxes: integration with equipment and site flows

We design the interface between the glove box and your reactors, furnaces, 3D printers, welding stations, potentiostats or spectrometers. Utility passages, electrical feedthroughs and handling devices are adapted to your temperatures and maintenance requirements. The goal: seamless integration, controlled cycle times and measurable reduction in exposure.

Typical use cases

- Air- or moisture-sensitive syntheses, formulation and solution preparation under argon/nitrogen.

- Welding and micro-assembly in an inert atmosphere to limit oxidation and porosity.

- Additive manufacturing of reactive powders and post-treatment in controlled confinement.

- Storage and transfer of pyrophoric or hygroscopic materials.

- Electrochemistry and deposits on substrates in low O2/H2O environments.

Support, qualification and sustainability

From the preliminary design stage onwards, we work in co-engineering to define your objectives, risks and integration constraints. The units are then developed on test benches with documented FAT, then installed on site with SAT and skills transfer to the teams. We provide leak test protocols and reports, reference O2/H2O checks and operating procedures tailored to your uses.

Over time, a preventive maintenance and sensor recalibration plan maintains performance. A critical stock of parts and upgrade kits ensure scalability without prolonged downtime. The objective: installations that are available, traceable and stable over time.

Inert gas protected processes in glove boxes: why choose Jacomex

Our experience with glove boxes and controlled atmospheres serves your safety, quality and productivity challenges. The Gsafe, Gbox and PureEvo ranges cover a wide range of uses, from standard workstations to customised architecture, making Inert Gas Protected Processes a reliable, traceable and optimised solution for your scientific and industrial objectives.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG