Glove Box for Inspecting and Testing Battery Components

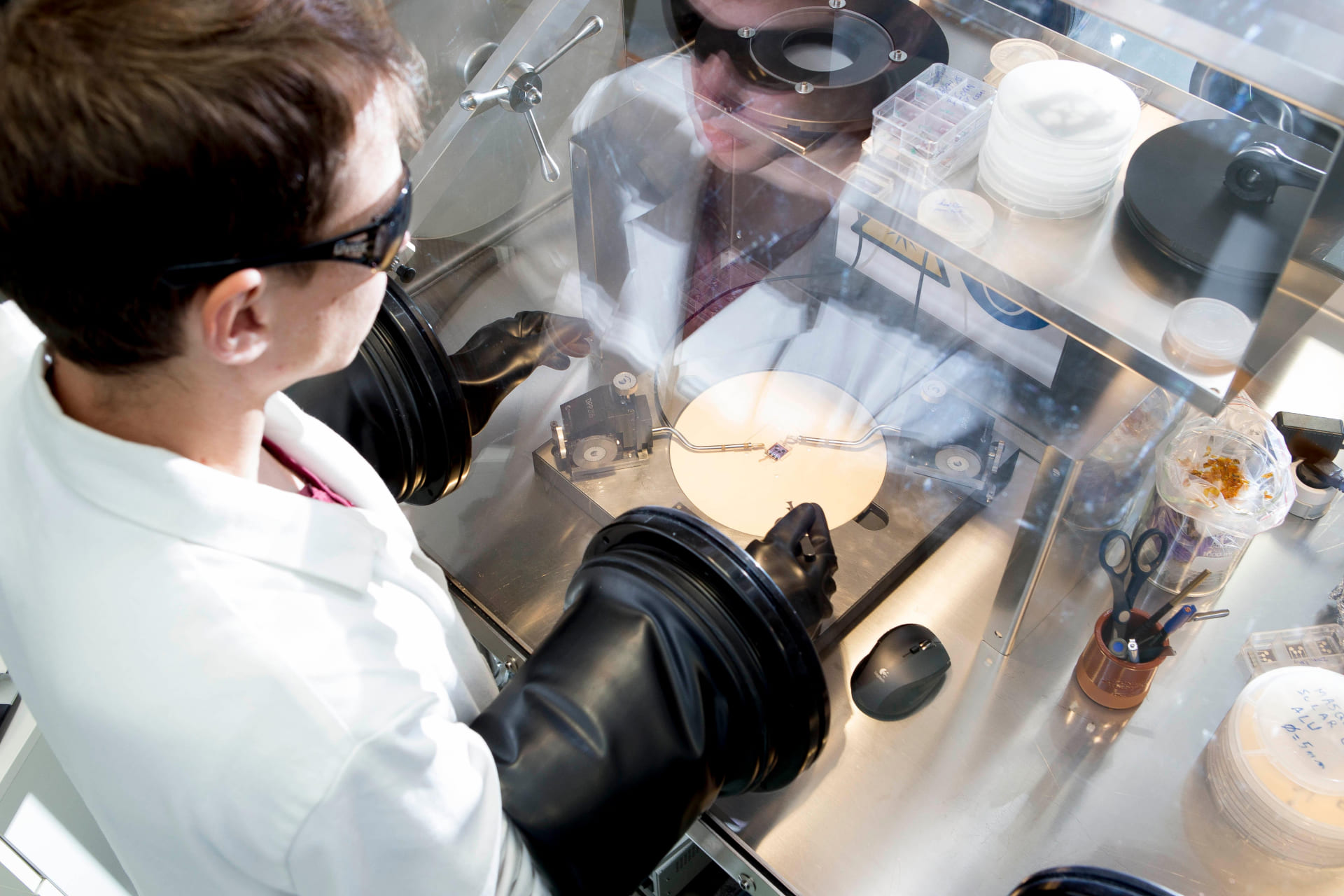

In the field of lithium-ion batteries and other energy storage technologies, inspecting and testing battery cells are crucial steps in ensuring their performance, safety and longevity. These processes require a strictly controlled environment to prevent contamination or unwanted reactions that could skew results or damage sensitive components.

Glove boxes for battery cell inspection and testing provide a sealed workspace under an inert atmosphere, protecting materials that are sensitive to oxygen and moisture. They allow technicians to safely handle and test battery cells while maintaining the integrity of the samples.

Main applications

Why use a glove box for inspecting and testing battery components?

Contamination prevention

The materials used in batteries, such as lithium, are highly reactive and can degrade rapidly in the presence of oxygen or moisture. A glove box maintains an inert atmosphere, typically composed of argon or nitrogen, eliminating the risk of contamination and ensuring optimal conditions for accurate testing.

Increased safety for operators

Inspecting battery cells may involve handling potentially hazardous or reactive substances. Glove boxes provide a physical barrier between the operator and the materials, reducing exposure risks and ensuring safe handling.

Reliability of tests and measurements

A controlled environment is essential for obtaining reliable data during electrochemical testing and performance measurements. Glove boxes help maintain stable conditions, eliminating external variables that could affect results.

Glove boxes for battery cell inspection and testing: our solutions tailored to your needs

The PURE range: standardised glove boxes for various applications

To meet the specific requirements of battery cell inspection and testing, we offer the PURE range, which includes:

- PURESMART: A compact, fully equipped glove box, ideal for laboratories and research centres. It is equipped with a self-contained purification unit, automatic pressure control and a transfer lock with vacuum pump.

- PUREMOD: This modular version offers increased flexibility, allowing adaptation to the specific needs of industrial processes or advanced research projects.

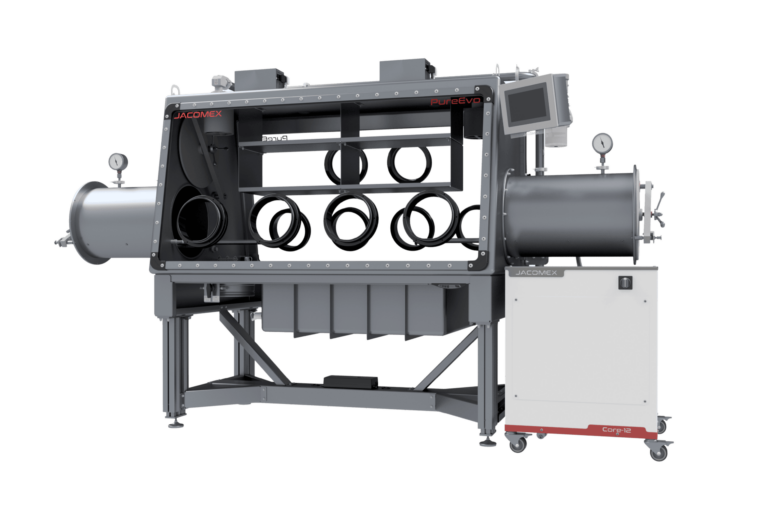

- PUREEVO: Designed for the most demanding applications, this high-end glove box is fully customisable and incorporates cutting-edge technologies for optimal performance.

All glove boxes in the PURE range are equipped with Energy Saving mode, an environmentally friendly feature that reduces energy consumption without compromising performance. This option is included free of charge in all our models, reflecting our commitment to sustainable solutions.

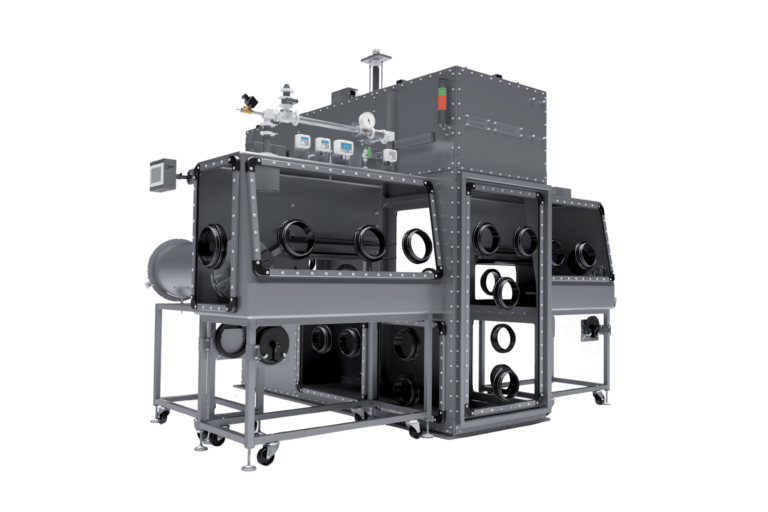

G(MEGA): the glove box for large volumes and complex processes

For large-scale industrial installations requiring an extended workspace, we offer the G(MEGA). This modular glove box can reach a volume of up to 150 m³, facilitating the integration of complex processes, robots and welding applications. Already used in sectors such as additive manufacturing, shipbuilding and aerospace, the G(MEGA) is suitable for all industrial processes that need to be carried out in a controlled atmosphere.

Industrial applications and flexibility of our solutions

Glove box for battery cell inspection and testing: research and development

In laboratories working on new battery technologies, our glove boxes enable safe handling of sensitive materials, accurate testing and prototype development under optimal conditions.

Industrial production

For battery production lines, our solutions ensure rigorous inspection of cells, guaranteeing their quality before they are integrated into modules or packs. The use of glove boxes reduces the risk of defects and improves the reliability of finished products.

Battery recycling

The processing of end-of-life batteries requires the handling of potentially hazardous materials. Our glove boxes provide a safe environment for the dismantling, analysis and recycling of components, contributing to responsible waste management and the recovery of valuable materials.

Why choose Jacomex glove boxes?

- Recognised expertise: With decades of experience, we are leaders in the design and manufacture of glove boxes and purification systems for various industries.

- Quality and reliability: Our products are designed to meet the most stringent standards, ensuring optimal performance and a long service life.

- Personalised service: We support our customers throughout their project, from needs analysis to equipment installation and maintenance, including user training.

Inspection and testing of battery components are essential steps in ensuring the performance and safety of energy storage systems. Our glove boxes provide the controlled environment needed to carry out these sensitive operations. Whether for research, production or recycling, our solutions can be tailored to your specific needs, combining innovation, safety and environmental friendliness.

Contact us today to discuss your projects and find out how our glove boxes can optimise your battery cell inspection and testing processes.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG