Glove Box Systems for Electrode Manufacturing

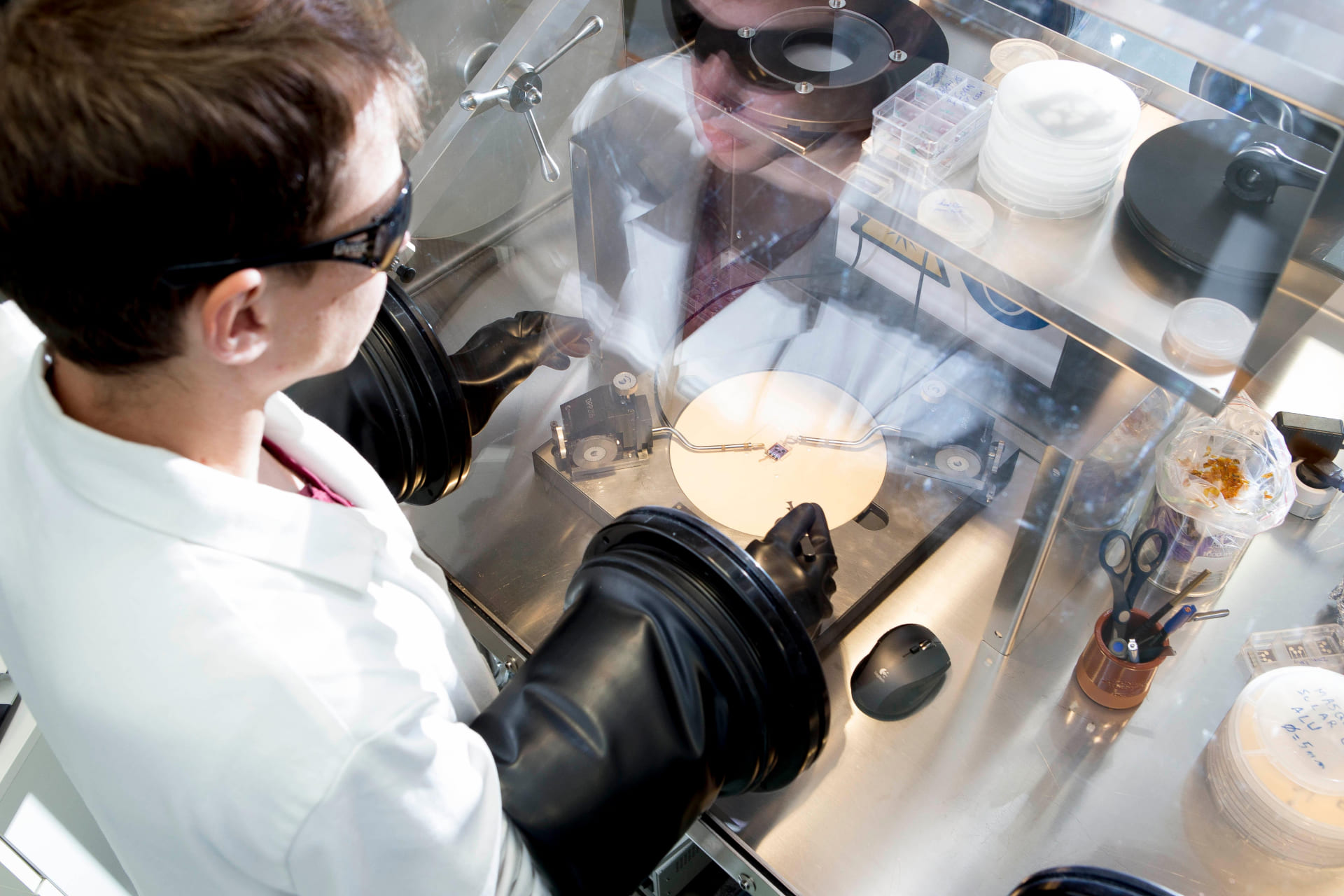

In the lithium-ion battery, supercapacitor and electrochemical device sectors, electrode manufacturing requires a perfectly controlled environment. Exposure to oxygen and humidity alters the properties of materials and compromises the performance of finished products.

Our glove box systems for electrode manufacturing allow work to be carried out in an inert atmosphere, thus ensuring the chemical stability of the components and the optimal quality of the electrodes produced.

Why choose Jacomex glove boxes?

Recognised expertise and innovation

With several decades of experience, we support manufacturers and laboratories in their projects requiring a highly controlled environment. Our equipment is renowned for its robustness, modularity and compliance with industry standards.

Tailor-made support

We offer a comprehensive support service, from equipment design to installation and maintenance. Our technical team is available to adapt each solution to the specific constraints of our customers.

We are convinced that electrode manufacturing cannot be optimised without an ultra-controlled environment that guarantees optimal quality and performance.

Thanks to our glove box systems for electrode manufacturing, we offer solutions tailored to the needs of manufacturers and laboratories working on batteries, supercapacitors and other electrochemical devices.

Contact us now to find out more about our equipment and benefit from tailor-made support.

Why use glove box systems for electrode manufacturing?

Protect materials from oxidation and moisture

Electrodes are made of sensitive materials, such as active powders, solid or liquid electrolytes, and certain polymer binders. When exposed to oxygen or moisture, these elements may lose conductivity, degrade rapidly, and have their electrochemical properties compromised.

By maintaining humidity and oxygen levels below 1 ppm, our purified glove boxes provide a stable inert environment that preserves the integrity of the materials.

Ensuring consistent, high-performance production

The controlled atmosphere of our containment systems enables more consistent and reliable electrode manufacturing. The controlled conditions ensure thermal and chemical stability of the materials, optimal repeatability and better adhesion of the electroactive layers, which are essential for the performance of batteries and supercapacitors.

Containment systems adapted to electrodes

Our advanced purification systems guarantee a fully controlled atmosphere, with high-precision sensors that continuously monitor oxygen and humidity levels. Thanks to secure transfer locks, any material or equipment introduced into the enclosure is protected against external contamination.

Modularity adapted to industrial needs

We offer flexible solutions, suitable for both research laboratories and industrial production units. Our glove boxes can be configured according to the specific requirements of each project, with options such as solvent extractors, integrated heating plates and devices for large-volume work.

Compliance with safety requirements

Our equipment complies with ISO standards and can be adapted to specific regulations, particularly for environments with explosion risks (ATEX regulations). Operator safety and material integrity are guaranteed throughout the manufacturing process.

Our solutions: the PURE range and the G(MEGA) range

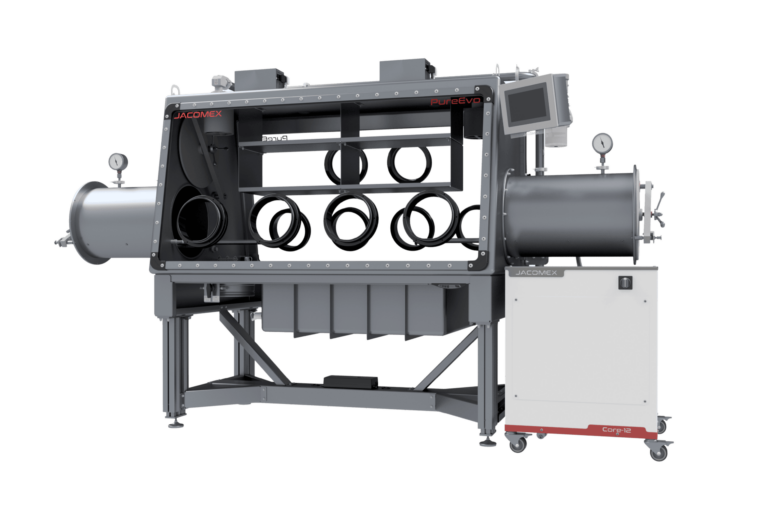

The PURE range, a solution for ultra-controlled environments

For electrode manufacturing, we have developed the PURE range, which is available in several models:

- PURESMART, a compact, high-performance glove box, ideal for laboratories and start-ups requiring an ultra-pure atmosphere.

- PUREMOD, a modular solution designed for advanced industrial processes, allowing the integration of scientific equipment.

- PUREEVO, a high-end glove box suitable for complex applications, offering maximum flexibility and exceptional performance.

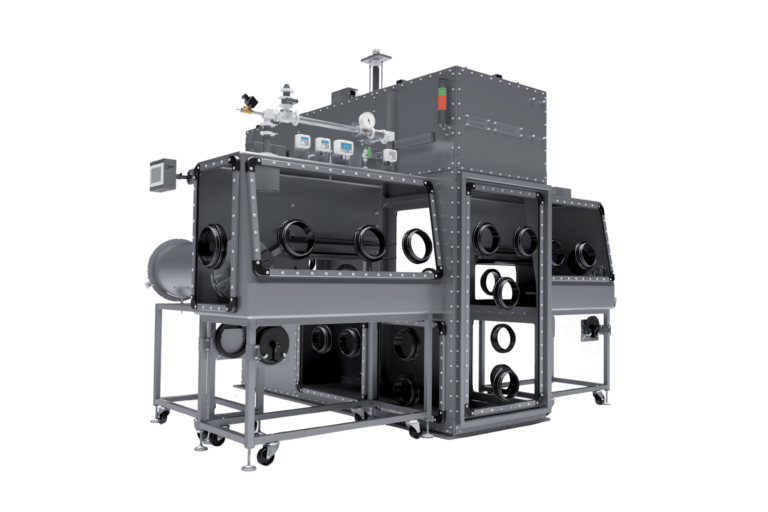

G(MEGA), the glove box for large volumes

To complement our PURE range, we offer G(MEGA), a large-volume glove box designed for industrial installations and large-scale projects.

This equipment can reach volumes of up to 150 m³, making it an ideal solution for integrating robots, automated systems and controlled atmosphere welding applications. Already used in the additive manufacturing, shipbuilding and aerospace industries, G(MEGA) guarantees unrivalled purity thanks to its latest-generation CORE 64 neutral gas purification units.

Glove box systems for electrode manufacturing: industrial applications and flexibility of our solutions

Key equipment for the lithium-ion battery industry

Our glove boxes are widely used in the manufacture of anode and cathode materials, providing a protected environment to preserve the properties of lithium metal, cobalt oxides and other sensitive components.

These solutions improve battery energy density, extend battery life and ensure long-term reliability.

A necessity for supercapacitors and electronic components

The manufacture of supercapacitors and other electrochemical devices requires a highly controlled environment. Our containment systems eliminate the risk of electrostatic contamination, ensuring maximum purity and chemical stability of materials.

Glove box systems for electrode manufacturing: essential tools for electrochemical research

Laboratories specialising in electrochemistry use our glove boxes to test new electrode formulations and conduct experiments under strictly controlled conditions. Our equipment ensures reproducible results, which are essential for the development of new energy technologies.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG