Glovebox for Battery Cell Assembly

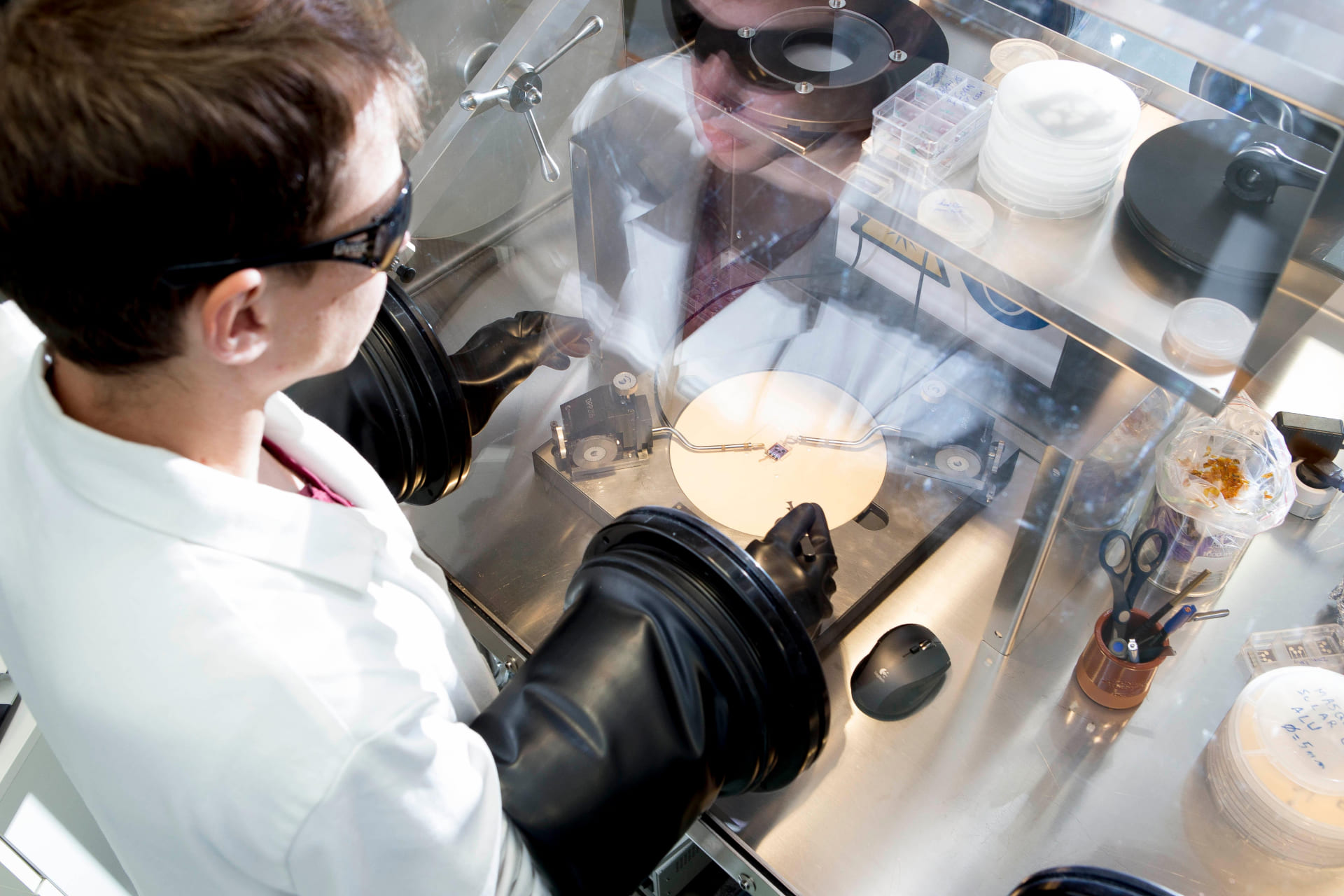

The assembly of battery components is a key step that determines the performance and reliability of lithium-ion batteries and other energy storage devices. These components, which are sensitive to moisture and oxygen, require a strictly controlled environment to prevent premature degradation of the active materials and ensure maximum safety during handling.

Our glove boxes for battery cell assembly are specially designed to provide a workspace under an inert atmosphere, ensuring optimal protection of materials and production that meets the most stringent quality requirements.

Main applications

Glove boxes for battery assembly: why choose Jacomex glove boxes?

We provide manufacturers and researchers with tailor-made solutions adapted to the requirements of battery assembly. Thanks to our recognised expertise, we guarantee equipment that combines reliability, performance and ergonomics.

Our glove boxes are designed to integrate easily into production lines, providing a secure environment and optimal protection for materials and operators.

We support our customers at every stage of their project, from the choice of equipment to its installation and maintenance, thus guaranteeing a turnkey solution tailored to their needs.

The assembly of battery components requires a highly controlled environment to ensure optimal performance and maximum safety. Our purified glove boxes offer a reliable and high-performance solution for manufacturers and laboratories wishing to guarantee a contamination-free assembly process.

Contact us today to discover our solutions and benefit from our tailor-made expertise!

Why use a glove box for battery assembly?

To protect materials that are sensitive to air and moisture

Lithium-ion batteries contain components that are particularly reactive when exposed to ambient air. Electrodes, electrolytes and structural materials must be handled in an environment that is completely free of oxygen and moisture to prevent chemical degradation.

When an electrolyte comes into contact with moisture, it decomposes and can generate unwanted gases that affect battery performance and life. Similarly, anode and cathode materials undergo oxidation reactions that alter their electrochemical properties. Working in a purified glove box prevents these risks and ensures flawless production.

Ensuring operator safety

Battery assembly involves handling reactive substances, some of which may pose a risk of ignition or toxicity. A closed and secure environment protects operators from potentially hazardous vapours and reduces the risks associated with handling fine powders and volatile liquids.

Our glove boxes allow total control of the atmosphere, thus limiting the risk of explosion or uncontrolled chemical reactions. Thanks to a high-performance filtration and purification system, they guarantee optimal protection for technicians while ensuring a stable environment for the materials being handled.

Ensuring consistent quality and uniformity

Batteries must meet very demanding quality criteria, particularly in terms of capacity, service life and safety. Assembly in a stable environment reduces the defect rate and ensures perfect cell uniformity.

Thanks to glove boxes, each step of the process can be carried out without external interference, thus guaranteeing consistent quality across all batches produced. This allows manufacturers to limit rejects and optimise their yield while complying with industry standards.

Glove box for battery component assembly: our solutions

An ultra-clean and perfectly controlled environment

Our glove boxes are equipped with advanced purification systems that eliminate all traces of oxygen and moisture from the working atmosphere. High-precision sensors provide continuous monitoring, ensuring optimal purity throughout the assembly process.

Materials can be safely introduced and removed through hermetic transfer locks, preventing accidental contamination. The equipment is ergonomically designed to facilitate handling while offering optimal comfort for operators.

Equipment adapted to industrial needs

Our solutions are suitable for both R&D laboratories and industrial production sites. Depending on requirements, our glove boxes can be configured to incorporate specific devices such as heating plates, welding tools or precise dosing systems for active materials.

Thanks to their modular design, they are scalable and easy to integrate into production lines, ensuring that they can be adapted to changes in industrial processes.

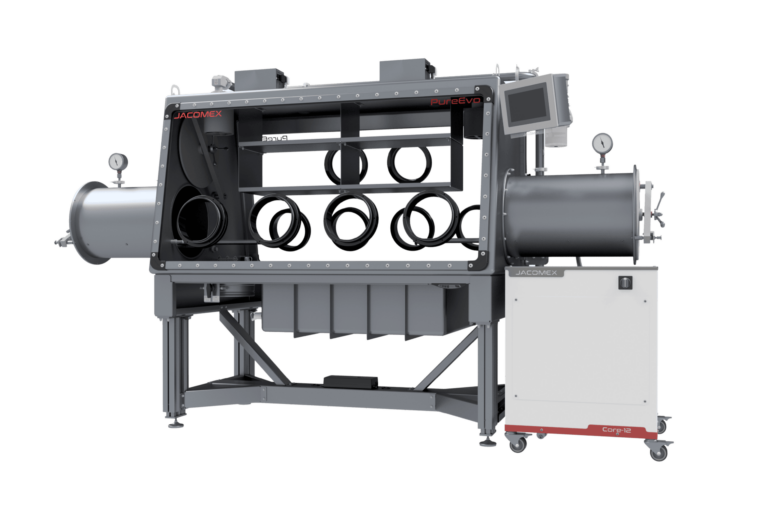

Glove box for battery assembly: the PURE range and the G(MEGA) glove box

A tailored solution with the PURE range

To meet the specific requirements of battery assembly, we have developed our PURE range, which is available in several models tailored to the needs of manufacturers and laboratories:

- PURESMART, a compact, high-performance glove box, ideal for start-ups and research centres requiring an ultra-pure atmosphere.

- PUREMOD, a modular solution offering great flexibility, perfect for production lines or experimental processes requiring the integration of additional equipment.

- PUREEVO, a premium model designed for complex applications requiring unrivalled performance and advanced customisation.

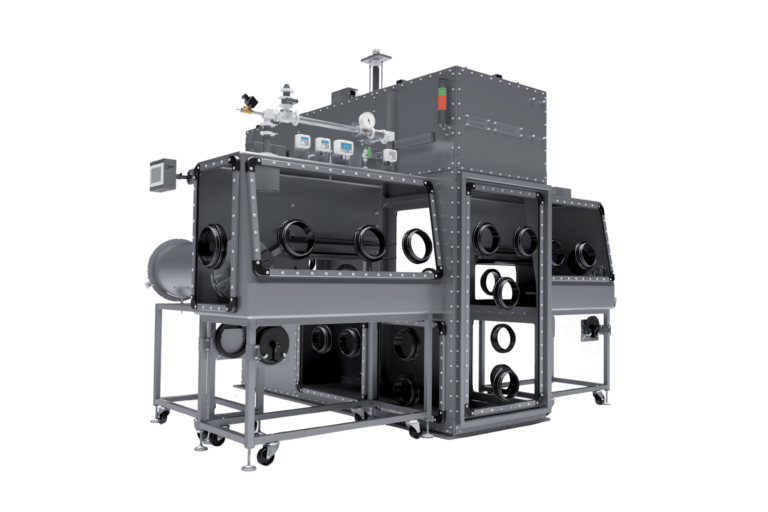

G(MEGA), the solution for large volumes

In addition to our PURE range, we also offer the G(MEGA), a large-capacity glove box specially designed for industrial installations requiring a large workspace.

With a volume of up to 150 m³, it is ideal for the integration of robots, automated machines or inert atmosphere welding systems. Already adopted in the additive manufacturing and aerospace sectors, it guarantees a highly controlled environment and exceptional purity thanks to our CORE 64 gas purification units.

A wide range of industrial applications

Glove boxes for battery component assembly: essential tools for lithium-ion battery production

Our glove boxes are widely used in the manufacture of lithium-ion batteries, ensuring optimal working conditions for handling sensitive materials. They optimise battery life and improve energy performance by preserving the purity of electrodes and electrolytes.

A major asset for research and development

Laboratories working on new generations of batteries use our systems to experiment safely and guarantee reliable results. The inert atmosphere allows new chemical compositions to be tested without the risk of alteration due to the external environment.

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG