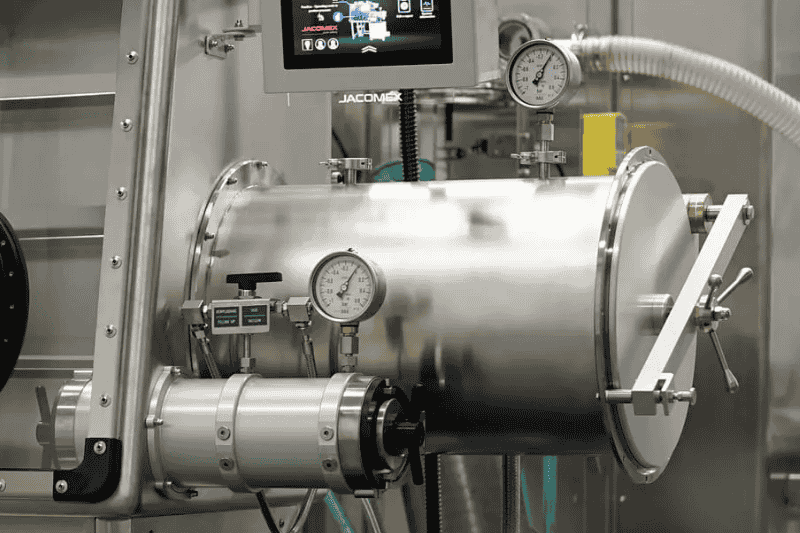

Cylindrical Vacuum Chamber for Glove Boxes

Overview

Vacuum Chamber

Description

The standard design of vacuum chambers is cylindrical. These are double door airlocks with lockable closure. They allow for the transfer of samples, instruments, tools, components etc. without any loss of containment of the enclosure to which they are connected.

Technical specifications - Information

Technical specifications of the Vacuum chamber:

|

Material: US AISI 304L stainless steel

|

|

Standard models: internal Ø 150 – 400 mm

|

|

Models on request: internal Ø 250 – 300 – 500 – 600 mm

|

|

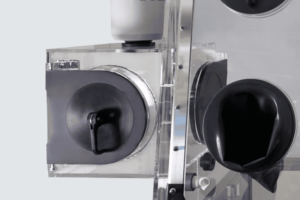

Doors Ø 150: quick-release or hinged

|

|

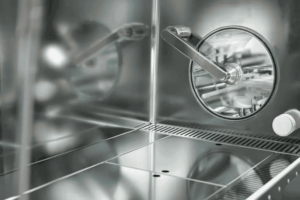

Doors Ø 400: hinged with capstan clamping, quick-lock for quick blocking in low position, lifting jacks outside the glove box for both doors

|

|

Sliding and removable tray

|

|

Vacuum gauge and manual/automatic control valves depending on models

|

|

Right or left mounting

|

|

Leak rate < 10-5 mbar.l/s

|

Vacuum airlocks are used exclusively on installations under controlled atmosphere (nitrogen, argon, helium), purified glove boxes, anaerobic enclosures or climatic glove boxes. For correct and safe use, the opening of a door should only be authorized after checking that the second door is closed. Their operation is based on vacuuming (thanks to a vacuum pump) and alternatively filling the chamber with gas in order to evacuate the air from the airlock.

The user has the choice of carrying out a variable number of successive empty/fill cycles in manual or programmable automatic mode to best eliminate all traces of atmospheric pollutants.

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.

Equipment and Features

See our related products

Contact form

Need help or an offer? Contact us