What is Aseptic Isolation Technology?

The use of aseptic isolation technology is increasing due to the demands of site, line and, most importantly, product approvals. Manufacturers must therefore invest in this technology to comply with standards and regulations.

A work unit incorporating isolation technology has the following elements

- Tight physical barriers.

- A central work area with an automatic decontamination system, which ensures complete decontamination of the internal surfaces, thus increasing the control of contamination risks. In this zone, it is possible to establish an overpressure or under pressure environment with respect to the external atmosphere. The central work area has its own air treatment system developing a filtered, unidirectional air flow.

- A transfer area or isolator equipped with gloves, a decontamination system and a link to the central work area can be incorporated

- Transfer systems. These allow the introduction or removal of products from the central work area, without breaking the containment and conditions of the internal atmosphere. The most common transfer systems are the DPTE (Double Door for Tight Transfer).

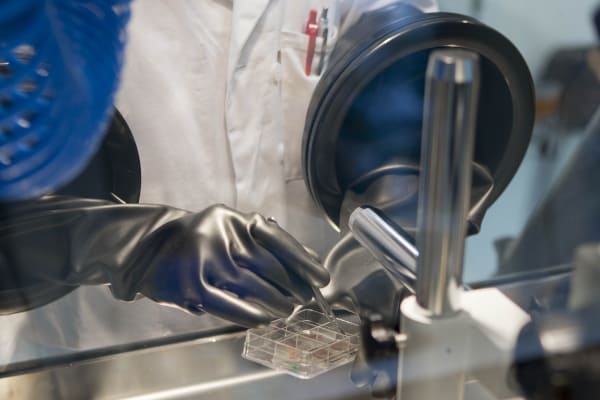

- Systems that allow operators to intervene in the central work area. Interventions are carried out without opening the doors. Gloves placed on the walls of the central work area allow the operators to handle the products.

Need a Professional in Aseptic Isolation Technology?

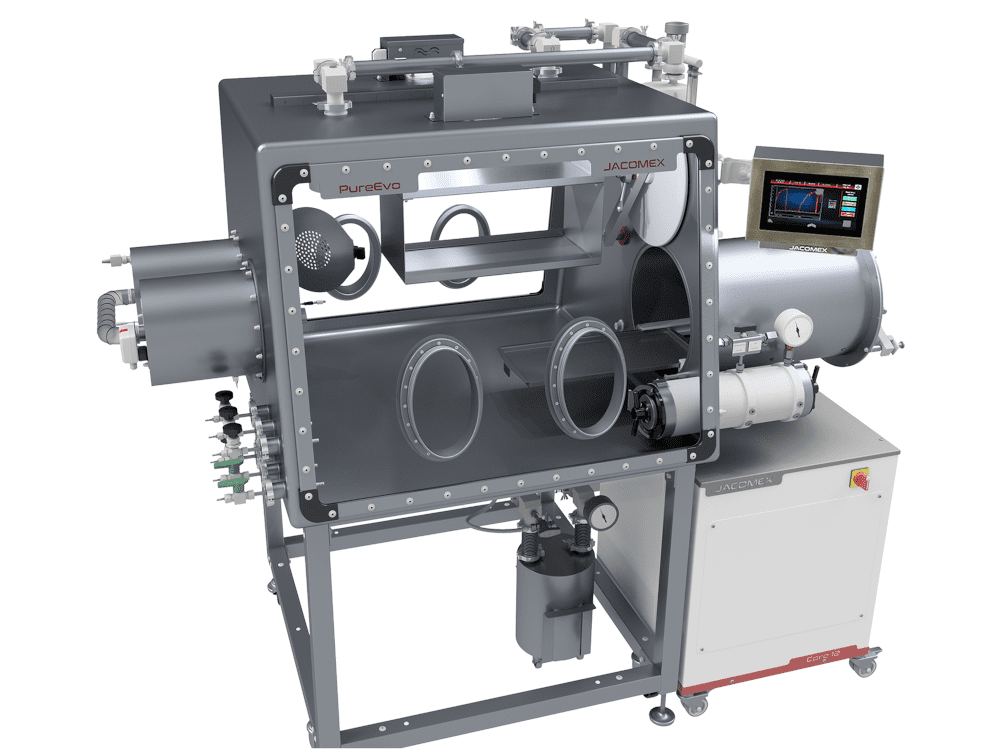

Jacomex has an unrivaled reputation in the design and manufacture of work units incorporating aseptic isolation technology. Our achievements in isolators are primarily based on state-of-the-art aseptic isolation technology. We manufacture stand-alone units as well as multi-station units. We use our expertise and structural configuration for various sectors (chemical, nuclear, biological).

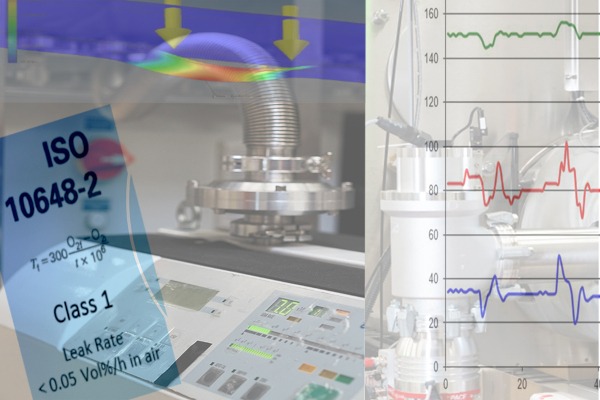

Jacomex is one of the pioneers in the design and manufacture of various isolators, which can be equipped with different transfer systems depending on their purpose (ventilated airlocks, Alpha Beta flanges, vacuum airlocks, Bag-In-Bag-Out). The isolators we offer are, of course, accompanied by certifications, alarms, safety features, documentation, are FAT-SAT tested and have IQ-QO qualifications.

In the medical and pharmaceutical sector, where the integration of aseptic isolation technology is essential, Jacomex is the specialist who can provide you with isolators with a tailor-made atmosphere.