The Need for Gas Management System

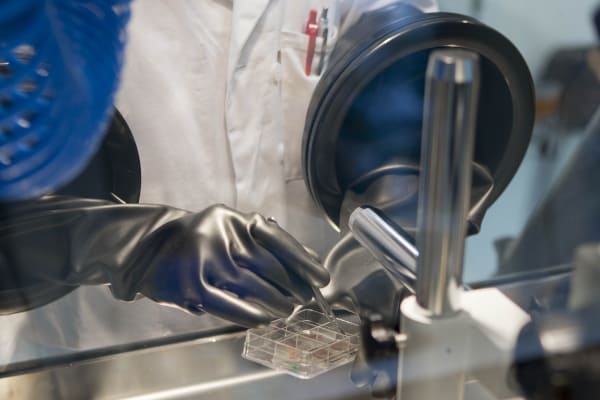

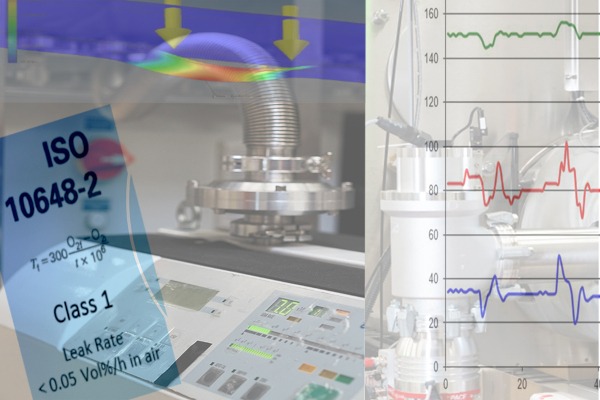

The gas management system (nitrogen, argon or helium) optimizes the use of a glove box. The glove box is used to confine processes or products under a controlled atmosphere. Thus, operations carried out inside the isolator or glove box can be done without any contact with oxygen or water. The hygrometry and the oxygen level of the internal atmosphere are maintained at a level below 1 ppm. The air is initially purged from the glove box before starting a neutral gas purifier. In order to create an inert environment inside the glove box and the isolator, it is necessary to purify and let the inert gas circulate over a gas purifier. For this purpose, a gas management system, with various devices integrated into the hermetic enclosure, is necessary. There are two techniques for inert gas use in glove box or isolator: lost and/or regulated open circuit flush and closed-circuit purification. If the first requires a significant consumption of inert gas, the second allows to save some gas. In addition to the exceptional gas quality obtained with a neutral gas purifier, its other advantage lies in its very low gas consumption due to this closed-loop circulation. The design of closed-loop purification systems helps with monitoring, control and recycling of inert gas. The gas management system is designed as a unit where it is discreetly integrated in isolators and glove boxes.

Components that Ensure the Safety of a Glove Box

A glove box, in addition to the gas purifier, must have several components to ensure its safety and proper operation. Thus, on an isolator or glove box, there must be safety valves, humidity and oxygen sensors, regulators and alarms. It is also necessary to equip a glove box with a hydraulic guard to evacuate excess gas and avoid excessive internal pressure. Depending on the sector, each operation requires various containment conditions (protective gas, pressure, temperature, etc.). Regulators therefore help to control the working environment. Gas management systems also improve the inert gas purification system. They are the perfect solution to gas consumption and safety problems. It is possible to request a quotation for Jacomex gas management systems. We offer personalized project management depending on your needs and the isolator or glove box application.