Functions of an isolator for sterile conditioning

The isolator for sterile conditioning is a bacteriologically sealed enclosure used to isolate an area. It is specially designed to prevent human or environmental contamination of the internal area. Its atmosphere can be controlled. If potentially hazardous intravenous formulations, compounds or agents are required to be handled, a vacuum isolator can be used. This is widely used in pharmaceutical laboratories. As a separator chamber for sterile packaging, the confined isolator meets the requirements of ISO Class 5 standards and the high standards imposed in the pharmaceutical industry.

This device has a dual function in the packaging of pharmaceuticals and potentially hazardous substances:

1. Containment

The isolator integrates a sterilization device to enable space containment during antiblastic and chemotherapeutic preparations, weighing or handling of pharmaceutical compounds, transfers of pharmacy materials or equipment, etc. The enclosed volume can be sterilized by means of a sterilizing agent.

2. The transfer of products or materials

The isolator, which is hermetically sealed, aseptic and separated from the external environment, can be used for products as well as packaging, tools and pharmacy equipment. For maximum protection, it is equipped with communication systems allowing the insertion and removal of the elements to be protected without breaking the containment.

Design of the Isolator

As a rule, the isolator has a stainless steel structure. In addition to its communication system, it incorporates several components.

The corners of the confined isolators are systematically rounded and seamless to optimise the cleaning and decontamination of the enclosure and to avoid the risk of cross-contamination. HEPA or ULPA filters allow the exchange of air between the isolator and the outside environment. In the case of laminar flow, these filters also ensure air circulation is in the same direction, generally vertically, which avoids the transfer of contaminating agents to the outside and keeps the atmosphere under controlled particulate cleanliness (ISO 14644-1 standard). In the case of an isolator operating in turbulent flow under vacuum, priority is given to the protection of the operators, their environment and the sterilization of the enclosure.

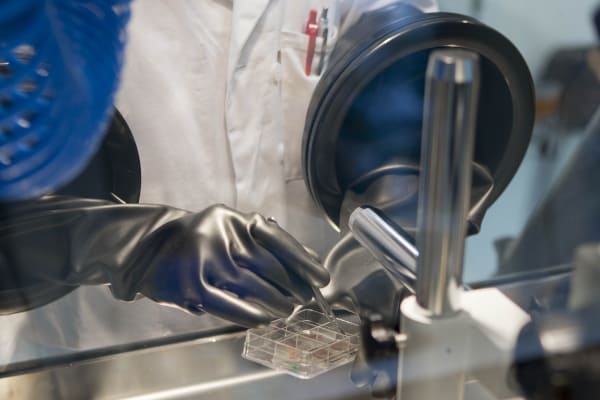

To give the operator access to the workstation, one or more pairs of gloves are attached to the transparent walls of the workstation. These gloves are standard size and multi-purpose most of the time. The light and transparency of the walls are used to optimize visibility. In this way, the operator can work while remaining outside the containment area, and thus protected against (micro)biological risks.

The isolator is also equipped with lockable, flip-up work surfaces. These allow the cleaning of the isolator following a pre-cleaning to be completed and the instrumentation to be loaded or unloaded with ease. A built-in safety device prevents accidental opening of the panel to prevent any risk. This is why operators choose to opt for tailor-made isolator models instead of the standard models available on the market. Nevertheless, manufacturers also provide modular highly confined isolators to meet the increasingly high demands of the industry.

Various Advantages of a Containment Isolator

The containment isolator is a much more efficient iso-technical facility than a clean room for the implementation of pharmaceutical processes. It also has the following advantages.

A high level of sterility and safety

When the process requires a controlled environment, the isolator ensures a high level of sterility and safety. The vacuum or overpressure operation ensures a higher level of sterility than in a clean room. It is particularly suitable for handling toxic or CMR products, sterile products, infectious or radioactive substances, and elements in an inert atmosphere.

Guaranteed sterility over time

The containment isolator must comply with class A standards (GMP EU classification OJ 07/01/97) to guarantee the long-term sterility of pharmaceutical products. It thus meets the pharmaceutical standards in force. Consequently, it is essential to turn to a reliable manufacturer to acquire a certified isolator.

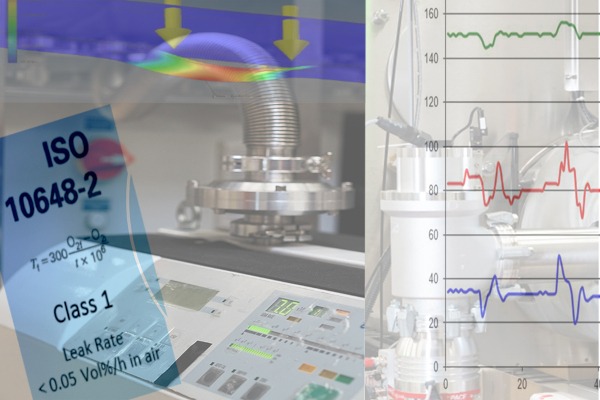

Monitoring and controls are made easier

An isolator makes it much easier to monitor and control humidity, temperature, pressure, sterility, etc. inside the chamber at each stage of the process. Integrated software enables monitoring and adjustment via a control panel. It is also equipped with pressure drop testing systems to detect leaks.

A more economical solution

A containment isolator is less expensive than a cleanroom in the pharmacy laboratory. It is more ergonomic and practical because of its reduced sterile volume. In addition, this equipment requires little maintenance, which reduces your operating costs.

Customisation and Options

It is entirely possible to accessorise a containment isolator depending on the type of process being carried out. Manufacturers can add connectors, accessories, software, etc.

Jacomex: the G(Iso) High Security Isolator

Jacomex is one of the world’s leading designers and manufacturers of glove boxes and isolators. For the containment of pharmaceutical and medical processes, the company is proud to present the G(Iso), its high security isolator under filtered gas.

The G(Iso) is a stainless steel isolator with rounded corners, which makes it possible to secure aseptic processes and to reinforce the protection of the operator. It can operate in a vacuum or overpressure under neutral gas. It can be used for handling active ingredients, cytotoxics or EPO4 – EPO5 products. It can also be used to weigh and repackage hygroscopic toxic powders, to carry out quality controls, to manufacture medical implants, etc. in a sterile atmosphere.

Thanks to its know-how and long experience, Jacomex offers you a practical technical solution to cleaning problems. This containment isolator has solutions for surface treatment and safe waste management, bag-in-bag-out boxes to simplify filter replacement…