What is additive manufacturing?

Additive manufacturing is a production process, which consists of manufacturing parts by adding material, based on a digital model, without a mould. Additive manufacturing is a technology that uses economical and efficient processes that have been revolutionising production methods and centres for several years.

This manufacturing concept aims to create parts or objects by adding material, layer by layer. These materials can be plastic, metal or metal powder. 3D printing is a common name for additive manufacturing. However, 3D printing and additive manufacturing have some differences.

3D printing is still limited and is most often intended for domestic use using additive technology. Additive manufacturing, on the other hand, refers to the manufacture of new, durable and complex components in an industrial context. It uses materials such as metal, ceramic materials or metal powders.

Precision and customisation are essential in many sectors (automotive, aerospace, energy, medical sectors etc.). This is why the process must enable the creation of prototypes and manufacture of metal parts that are fully functional in a short time. Additive manufacturing tends towards mass production of parts, with a more economical use of materials.

The advantages of additive manufacturing

Additive manufacturing has the advantage of offering greater efficiency to production centres. 3D printing is the most popular standard method of manufacturing industrial objects. However, additive manufacturing techniques have the potential to transform the way manufacturing and production are carried out. Industries which integrate these processes can reap real benefits.

The main advantages of additive manufacturing, whether it is based on metal powders, polymer materials or ceramics, are as follows

- Reduced costs and production time;

- Saving of used and reusable materials;

- Customisation of technical parts;

- Addition of new functionalities to manufactured parts;

- General reinforcement of the structure of the parts;

- Production of parts that cannot be manufactured using traditional machining methods.

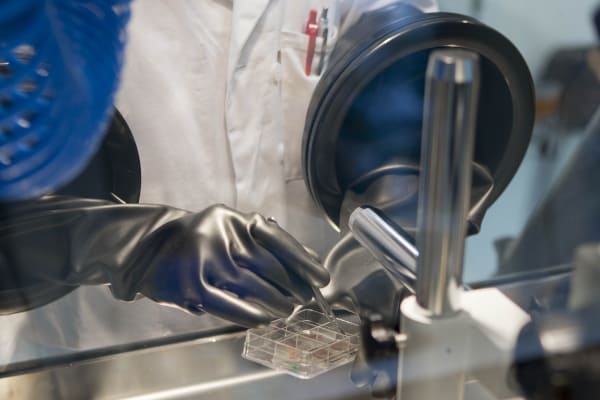

The use of a glove box in additive manufacturing with metal powder

The use of additive manufacturing requires, above all, a step-by-step security process. There are various uses, in particular

- Preparation of metal powders: this involves preparing the powders that will be used for the additive manufacturing process. The powders can be ground, sieved, weighed and repackaged as powders with a very fine grain size, often nanoparticle size. These steps must be carried out inside a glove box where humidity and oxygen levels are controlled. Jacomex designs containment systems that allow these steps to be carried out safely. Humidity control preserves the intrinsic characteristics of the powders, while oxygen control (elimination of oxygen) avoids the risk of flammability when in contact with air. Airlock systems allow for the safe transfer of powders into inert drums.

Jacomex designs custom-made glove boxes for the preparation of metal powders, allowing the workstation to be made safe and protecting the operators and the surrounding environment.

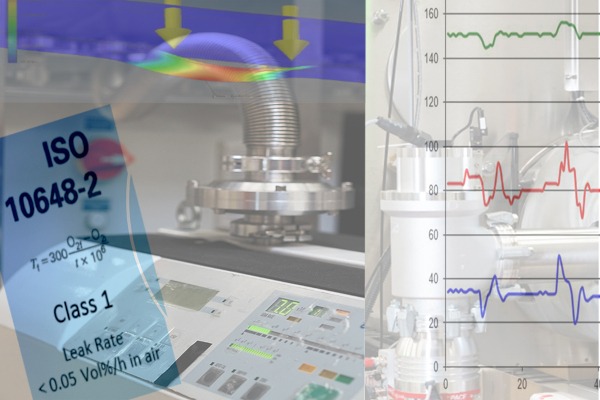

- Additive manufacturing: the combined use of a robot in additive manufacturing with fine metal powders makes it imperative to secure the manufacturing environment. A custom-made containment enclosure is usually designed with a controlled atmosphere, usually purified, allowing work to be carried out at very low oxygen levels, of the order of a few ppm to a few tens of ppm, even in enclosure volumes up to 100m3.

The company has specially developed a modular industrial enclosure of variable dimensions used in the additive manufacturing stages with the integration of a robot with a laser clamping head. An adapted work enclosure, secured in a controlled atmosphere purified by a large capacity purification unit.