Pharmaceutical Isolator for India

The use of an isolator in a pharmaceutical environment for aseptic manufacturing and various medical processes is essential, particularly in countries such as India, which has a worldwide reputation for excellence in the field. Regulations and standards are very strict. During the manufacture of surgical and medical implants, this specialized equipment is indispensable, especially when it comes to product containment.

The control and protection of the environment within the isolator prevents any form of contamination. It is a low-cost and more practical solution for meeting safety regulations and carrying out pharmaceutical processes. Filling, aseptic manufacturing and sterility testing, requiring an aseptic and confined environment, can be performed using the isolator.

Why Use a Pharmaceutical Isolator?

In the past, clean rooms or sterile clean rooms have been used for aseptic dispensing. Nowadays, processes require less sterile volume (i.e. not entire rooms) thanks to the advent of pharmaceutical isolators. Whether in India or elsewhere in the world, the isolator allows inexpensive implementation in the pharmaceutical and medical industry. It also offers more convenience and ergonomic.

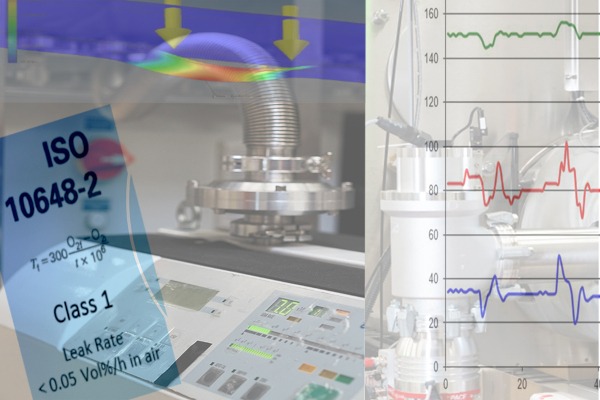

In order to comply with ISO standards, pharmaceutical regulations and GMP (Good Manufacturing Practice) requirements, a pharmaceutical isolator must meet precise specifications. Compared to clean rooms, it offers better sterility. The isolator also minimizes the risk of aseptic breakage during the aseptic process (from sterilization to sealing of the final package).

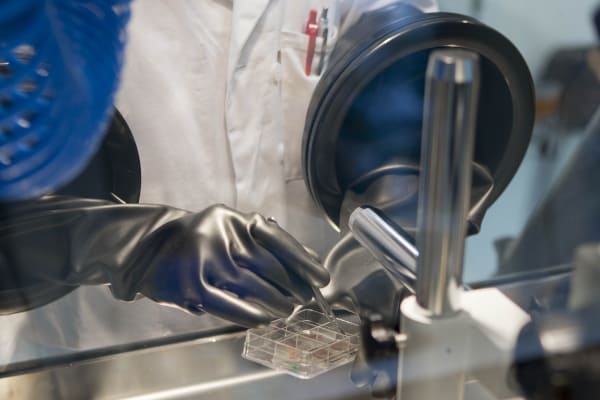

Within the pharmaceutical isolator, fillings of injectable products, various manipulations, etc. can be carried out away from particles and microorganisms that could compromise the products and/or the process. The environment inside this equipment is perfectly protected and confined. This keeps it away from any risk of contamination from the outside environment or humans. The isolator also protects personnel from any hazardous products during toxic processes.

Pharmaceutical Isolator for the India Market

Isolators are of particular interest to the pharmaceutical industry, especially for assemblies and operations requiring special conditions. Indeed, they meet the strict constraints of a specific process or the control of the atmosphere, whether gaseous or particulate.

The demands in the medical field are generally very specific and precise, with multiple applications generally involving microelectronics, biology, pharmacy or the protection of operators and products.

The pharmaceutical isolator allows the realization of aseptic distributions. In other words, it allows all productions requiring product protection and sterility tests in a confined and aseptic environment. This equipment has an hourly leakage rate of around 0.1 to 0.5% of its volume, that guarantees its effectiveness. Biodecontaminated by H2O2 (hydrogen peroxide), the device is also equipped with ULPA or HEPA (very high efficiency) filters, ensuring the isolation of the space from the external environment.

Generally speaking, software functions, accessories, facilitating its use and monitoring, as well as connectors are integrated into this equipment. At least once a year, it must be subject to various control tests.

Jacomex – Supplier of Pharmaceutical Isolators for India

Jacomex is one of the few suppliers of pharmaceutical isolators for India with a multidisciplinary technical background. The solutions proposed by the company combine the specificities of various sectors to produce a custom-made isolator that meets the most stringent specifications. The company controls all the stages in the development of each project: design, boilermaking, manufacturing, assembly, controls, tests.

Get a Free quote without obligation

Contact our commercial team to get a customized quote for an isolator made by Jacomex India.

They Trust Us

location

184 Avenue du Bicentenaire

Zone Les Prés Seigneurs

01120 Dagneux – France

Made in France

All of our products are designed and manufactured in France