Why use a temperature and humidity controlled glove box?

The controlled humidity (temperature and humidity) glove box is essential when a special atmosphere is required to protect products that are potentially dangerous for the operator. These products can be used in a totally anhydrous or low humidity atmosphere, with the temperature required by the process.

In addition to humidity and temperature control, the humidity glove box can be equipped with an oxygen eliminator if required. These are conditions that are required by experiments or R&D in certain biology environments for example. But the equipment is also very useful in the production of battery materials. The humidity controlled glove box is also used in TIG welding and many other industrial applications.

The equipment is also used in a variety of applications such as alkali metals, fine chemicals that are particularly reactive to moisture (sodium, lithium), development and production of supercapacitors, new functional materials and medical supplies, and the nuclear industry.

What are the characteristics of the glove box?

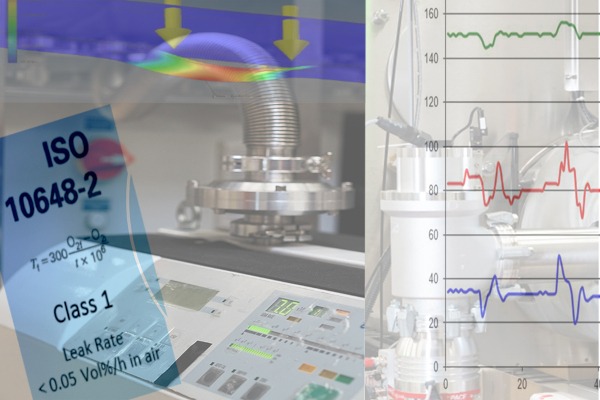

The manufacture of a humidity controlled glove box is useful for various applications where it is necessary for the temperature and humidity level to have a precise value, often below atmospheric conditions.

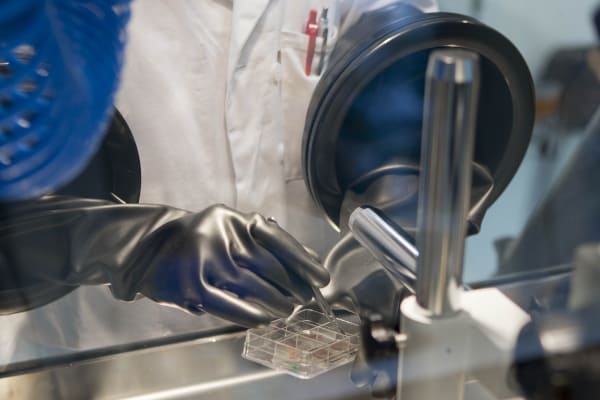

The operator accesses the protected area by using the handling gloves integrated in the walls of the glove box. For the introduction of the products, substances and instruments required for handling, transfer systems are provided for the operator.

The humidity, pressure and temperature levels inside the glove box can be adjusted. These can therefore be controlled using the integrated regulators, humidity sensor or humidity analyser.

The glove box also provides a highly secure containment area under an inert and pure atmosphere for the handling of hazardous substances. All of these advantages benefit high-tech industries, the pharmaceutical-medical sector, nuclear, R&D, aeronautics, etc. Areas where optimal safety and high performance are required.

In the industrial sector or in the research field, specific equipment is required when it comes to the implementation of thermal processes. If the processes also involve temperature control, the right equipment must be used. The use of a humidity and temperature controlled glove box is essential.

Which glove box model should I choose?

There is a wide variety of models on the market in terms of humidity controlled glove boxes. However, a temperature and humidity controlled glove box offers optimum protection for the handling of oxidisable, sensitive, pyrophoric or hygroscopic products. All this in a pure, inert and ultra-clean atmosphere. Thanks to a purification system under argon or nitrogen, humidity, oxygen and traces of solvents are eliminated.

At Jacomex, we are constantly innovating to ensure that temperature control and thermal process instruments in glove boxes meet the requirements of each sector. The glove boxes can therefore be designed according to the specific constraints that your processes require, and are, therefore, tailor-made. In addition, we also offer standard glove boxes, adapted to the various handling operations common in aeronautics, laboratories and industries.

Our company has multidisciplinary technical expertise, which enables us to offer you the best turnkey solutions. The design, manufacture, assembly and testing of our glove boxes are carried out on our site. Our engineers carry out the technical validation of the processes while the integrations and interfaces are designed and built by our experts.

If your glove box is equipped with heating trays, ovens or drying ovens, our design office will take care of the calculation and verification of the thermal effects.

The know-how and skills of our experts are used to ensure that the design of your humidity glove box (temperature and humidity) meets the requirements of your project. A free quote can be provided if you wish to have an overview of the cost of your equipment.

Jacomex, an expert at your side

With over 75 years of experience, Jacomex is an internationally recognised manufacturer. Our mission is to provide the best protection to our customers through innovation and R&D. The design, development and manufacture of our glove boxes and purification units is carried out in Lyon.

Our departments are made up of experts who work to develop solutions adapted to each field. Our teams are proud of the projects they have completed, which are often world firsts in the industrial sector.

We have sold and installed our equipment in over 60 countries and in fields as varied as the nuclear, research, pharmaceutical, medical, additive manufacturing, energy and organic electronics industries. Finally, we work in compliance with the standards that are specific to each field of application.