Process ovens

Process ovens

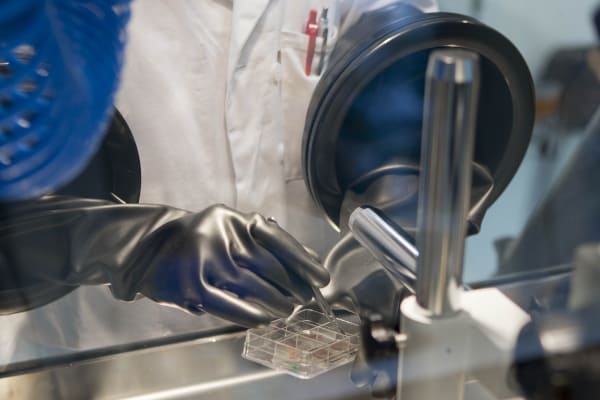

Process ovens are mainly used as high temperature furnaces for special processes in Production or Research. They are made on request only and meet detailed specifications. Depending on the information received and the desired process, their components may be made of different alloys such as 316L stainless steel, inconel, refractory steel in order to improve their performance in terms of thermal resistance, thermal conductivity, resistance to corrosion and wear…

They usually operate under vacuum and can also use different gases or mixtures. They can be used for melting small samples for glass production, air-sensitive metal alloys or ceramic powders, in heat treatment steps, in sintering processes or even annealing or tempering.

Applications

Technical specifications – Information

Technical data:

|

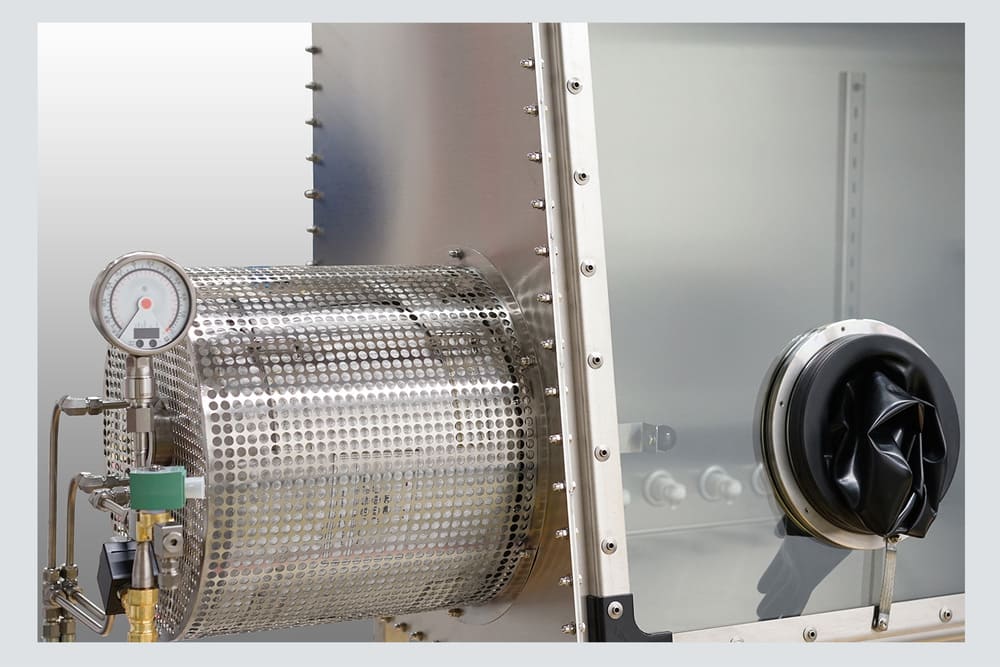

Made to measure in horizontal (sides – rear) or vertical (floor) mounting

|

|

Heating temperature between 300 – 1600°C

|

|

Diameter and heating length on request

|

|

Supplied complete with integrated electronic control, safety, power unit,

thermal insulation, cooling system and cooling flange |

Need help or an offer? Contact us

* Fields marked with an asterisk are required.